Description

Product details

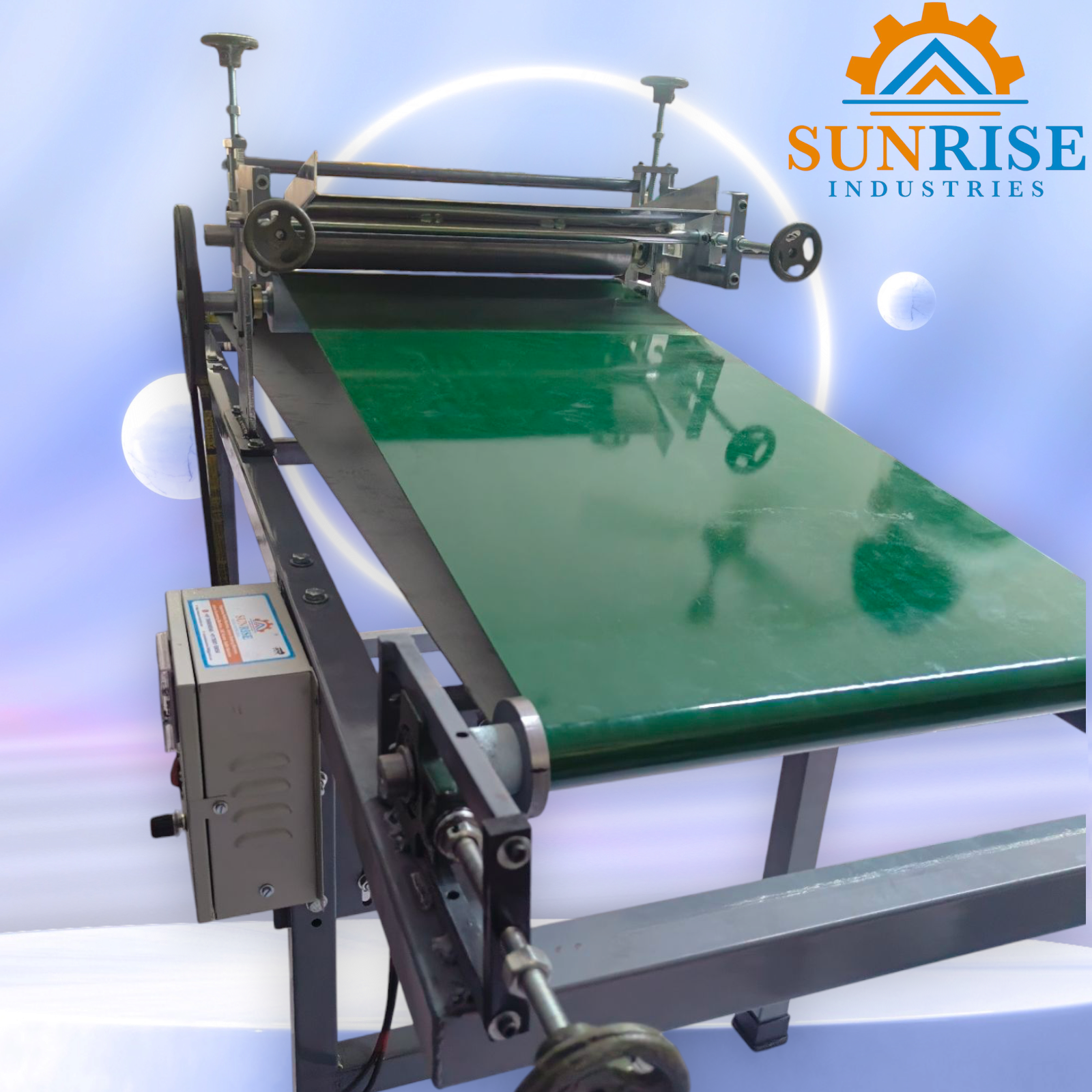

WORKING PROCESS OF JARKAN SHAKING MACHINE The working process of the Jarkan Shaking Machine involves several steps, designed to automate and streamline the placement of rhinestones, Jarkan stones, nail heads, and other decorative elements onto textile materials. Here's an outline of the typical working process: Setup: - The machine is powered on and set up with the required voltage (220 V). - The specific design template or pattern to be created is loaded into the machine's control system. Material Placement: - The fabric or material to be decorated is placed on the machine's work surface. - Depending on the machine, it may have an adjustable working size to accommodate different material dimensions (e.g., 16x24 inches, 18x30 inches, etc.). Stone Loading - The rhinestones, Jarkan stones, or other decorative elements are loaded into the designated feeding area of the machine. - The machine is capable of handling different sizes and shapes of stones, which are automatically sorted and positioned. Automatic Operation: - The machine begins its automatic process, where it uses vibration and shaking mechanisms to precisely place the stones according to the design template. - The automatic rise and decline feature helps in accurately positioning the stones and ensuring they adhere correctly to the fabric. Collection and Fixation: - Once the stones are placed, the machine may apply heat or pressure to fix them securely onto the material, depending on the specific machine's capabilities. - The process ensures that the stones are firmly attached and aligned with the desired pattern. Completion and Inspection: - After the decoration process is complete, the material is removed from the work surface. - The finished product is inspected for quality and accuracy, ensuring that the stones are correctly placed and secured. Safety Features: - The machine includes an emergency stop facility for safety, allowing operators to halt the process immediately if needed. Maintenance: - Regular maintenance is performed to ensure the machine operates smoothly, including cleaning the feeding mechanisms and checking the control systems. The machine's automated system and user-friendly interface significantly reduce labor and time while enhancing precision in creating intricate designs on textiles. Material Specification in JARKAN shaking Machine The Jarkan Shaking Machine is built with specific materials to ensure durability and efficiency. Here are the material specifications typically associated with this machine: Machine Material: - The main structure is usually made of mild steel, which provides strength and durability necessary for industrial operations. - Some components may also be coated for additional protection and longevity. Surface Finishing: - The surface is often color-coated to protect against rust and wear, enhancing the machine's lifespan and maintaining its aesthetic appeal. Other Specifications: - Weight: Approximately 240 kg, contributing to its stability during operation. - Phase: Single-phase, which is suitable for typical industrial power supplies. - Voltage: Operates on 220 V, a common standard for industrial equipment. - Frequency: Typically ranges between 40 Hz and 50 Hz, ensuring compatibility with various power systems. These material specifications ensure that the Jarkan Shaking Machine is robust, reliable, and capable of handling the rigors of continuous industrial use in the textile sector.