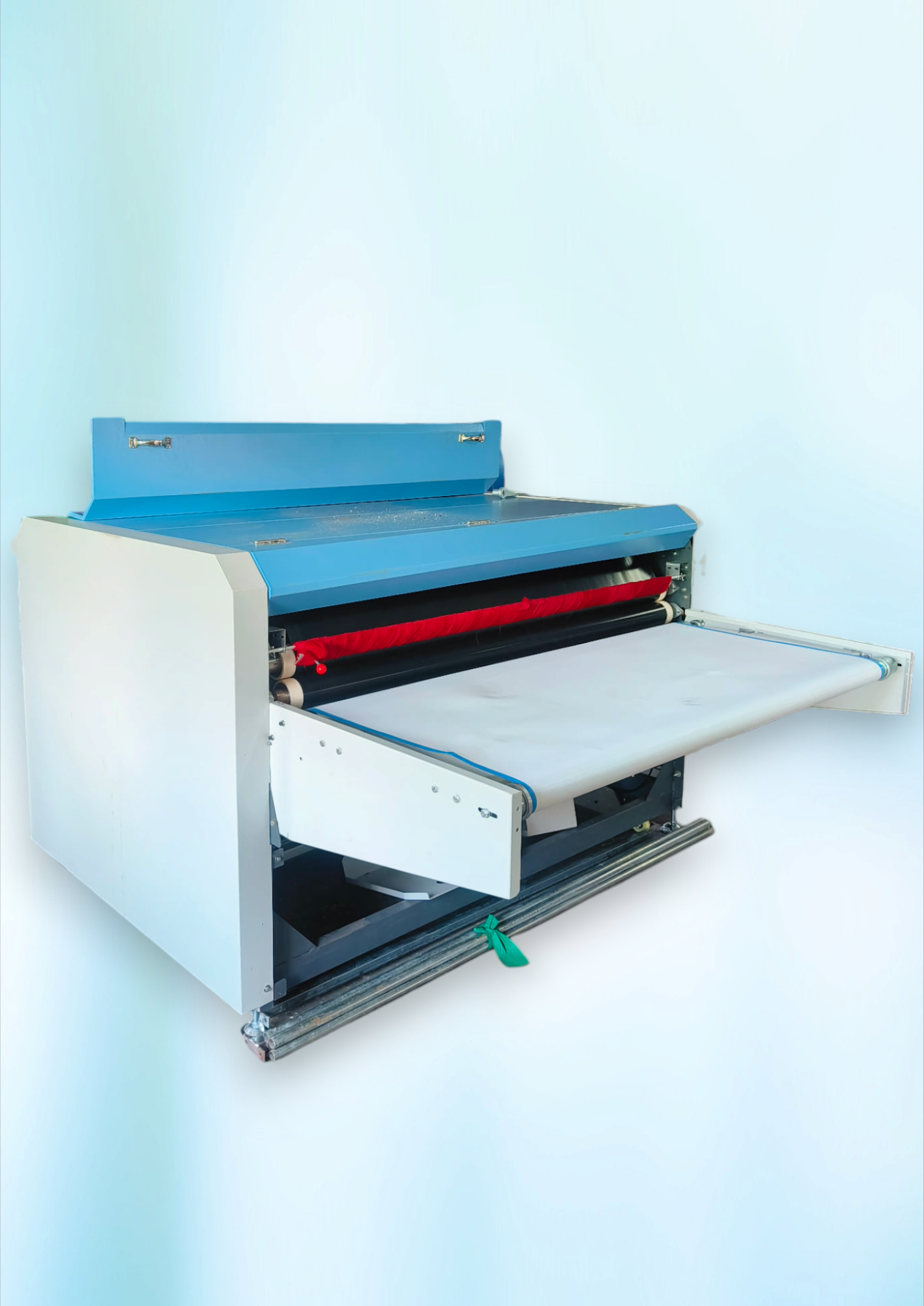

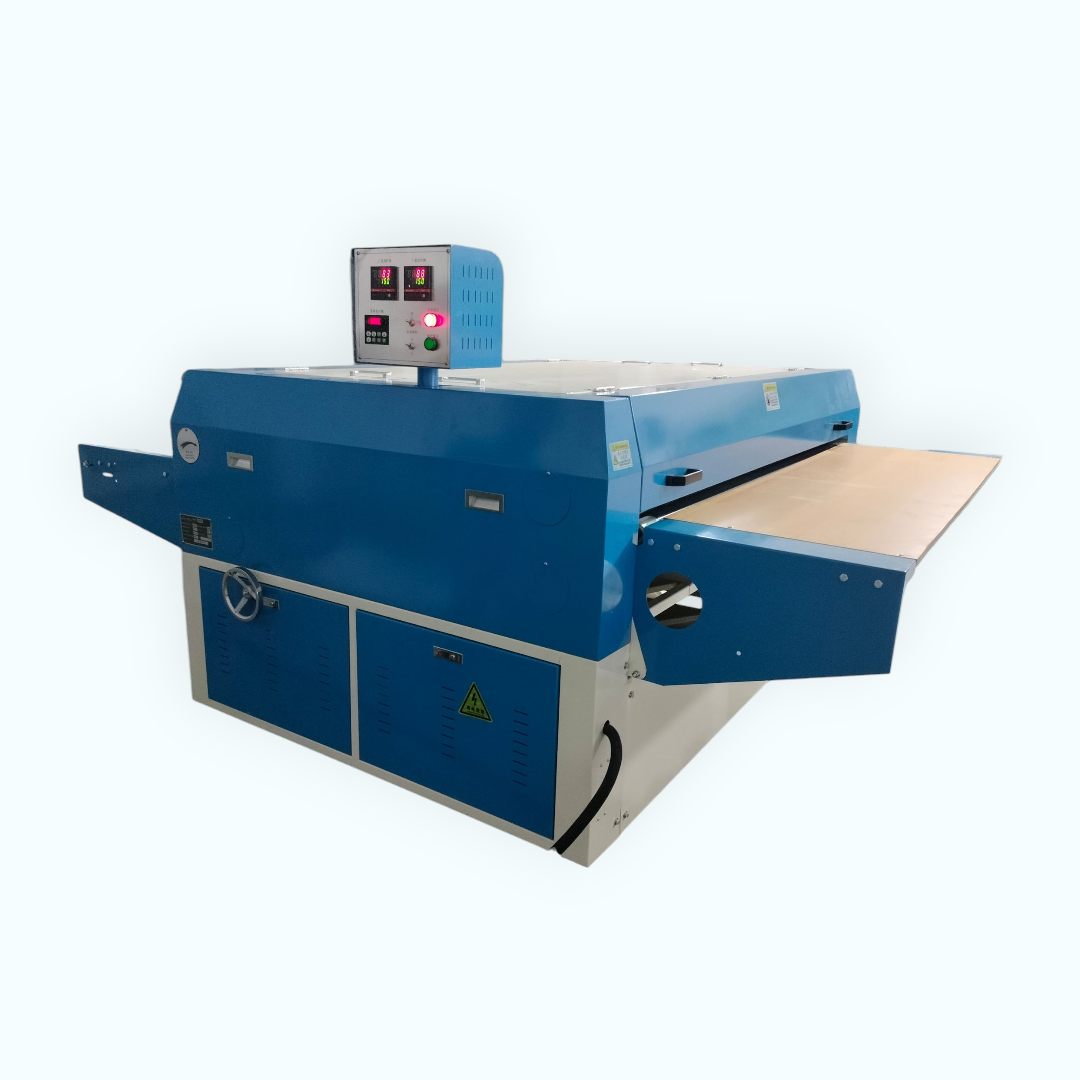

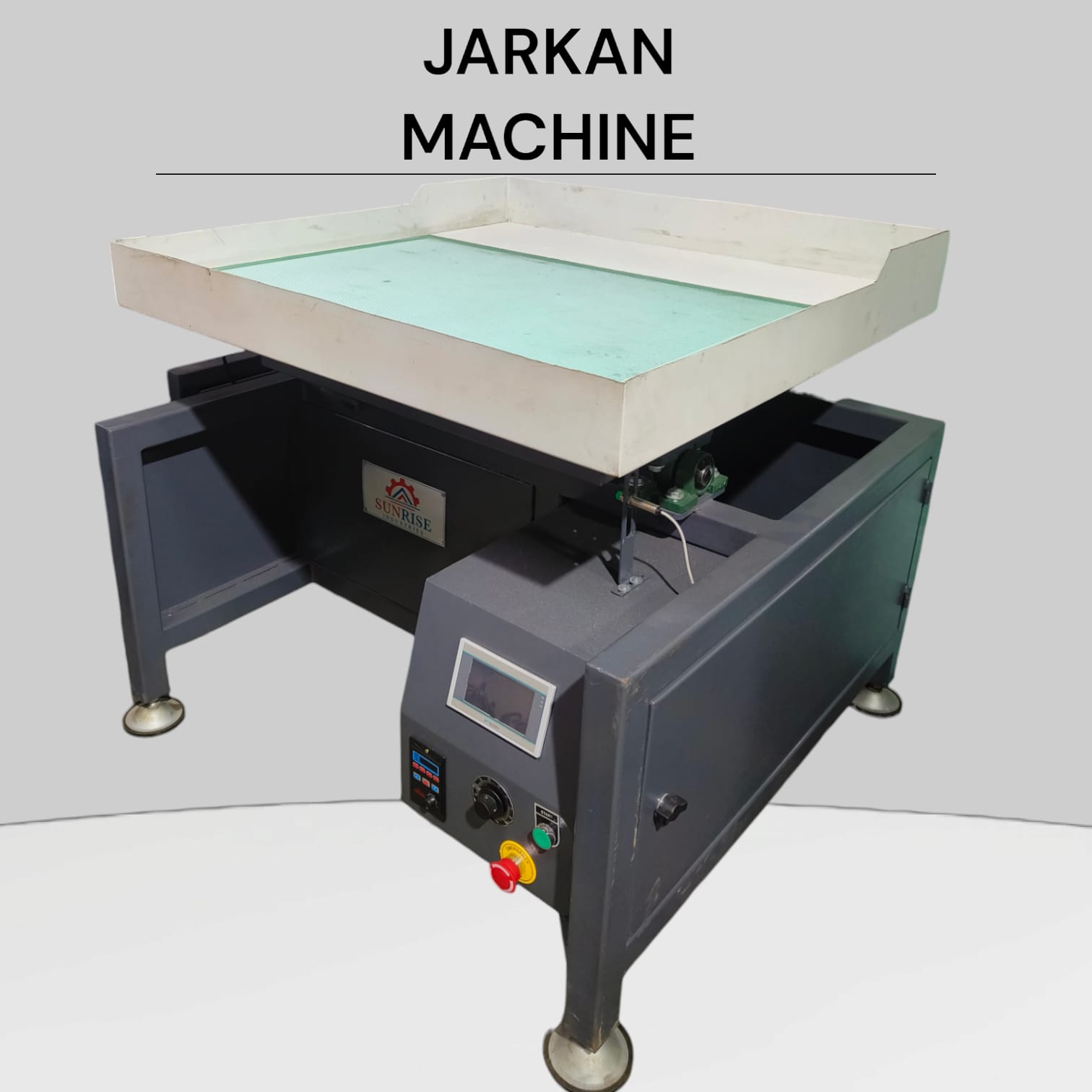

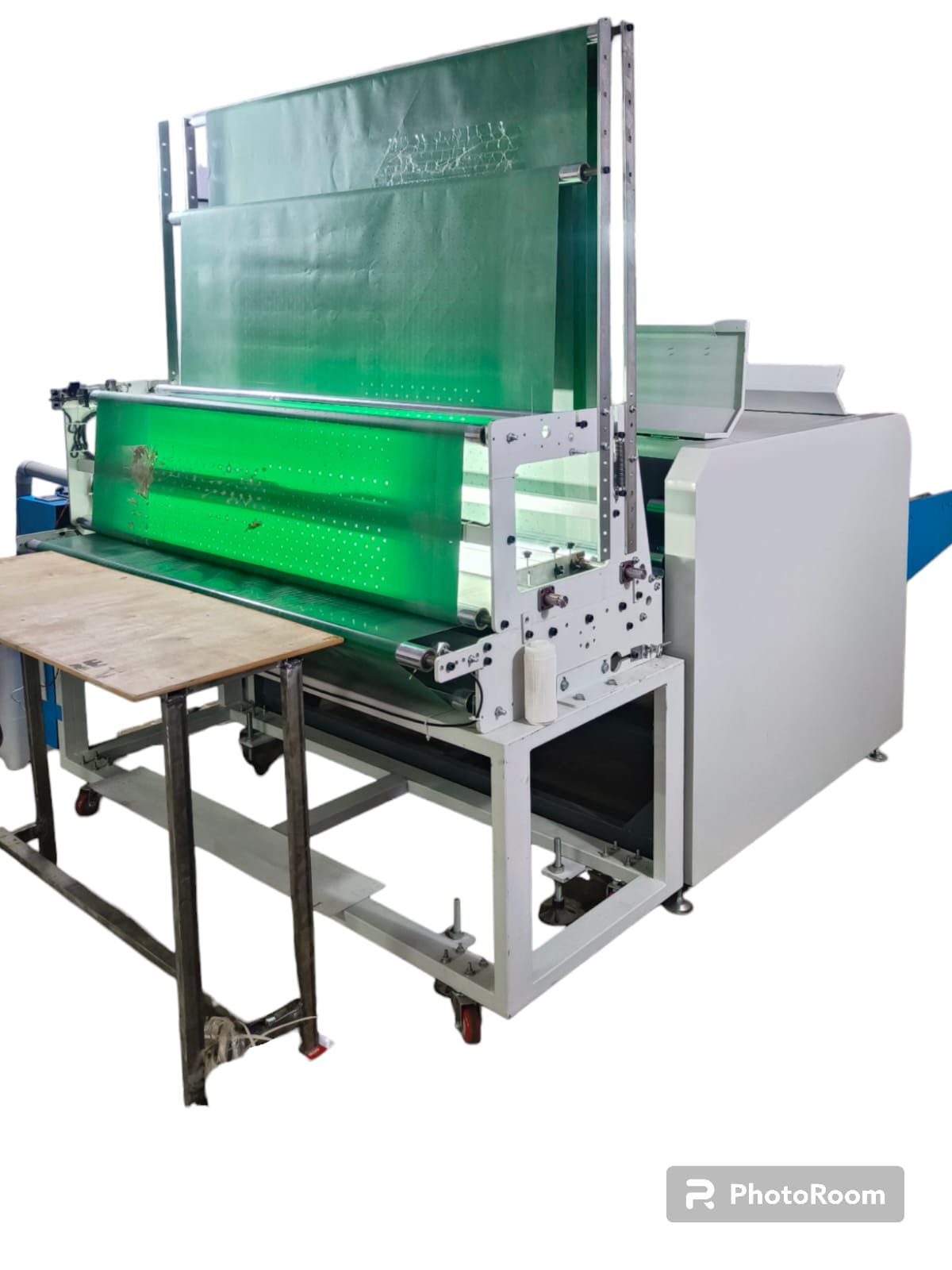

The feed sheet carries this part and the interlining to the fusing chamber. In the fusing chamber, the required pressure and heat are given. - To transmission of heat in the interlining, a direct or indirect method is applied. After applying heat, the required pressure is applied to the interlining with the help of a pair of rollers. - The surface of the roller is generally covered by hard rubber. With the help of spring or pneumatic power, the pressure is created in rollers. And there is an arrangement of increasing or decreasing heat. The preselected time is determined through the control of the speed of the endless feed sheet. - Just after fusing, the fused parts are removed carefully from the delivery sheet and in a flat condition. Because during removing of the fused part in a heated condition., any folds created there may be permanent. - One worker is persistently feeding, and another worker is ceaselessly accepting the fused parts on the conveyance side. - The production of a continuous machine is high, and the quality of the fusing is also good. In some machines, for double fusing, there is an automatic feedback system. This is the most used machine in the garments industry. These are often used to apply the best tape that sticks to fabric. - Fabric fusing is an important part of the garment production process. It involves attaching an interlining between parts of the garment fabric for increased strength and shape retention. What is Fabric Fusing Machine? - During fabric fusing, an adhesive resin is applied to one side of the interlining, and then bonded to another piece of fabric by applying heat and pressure. The resin solidifies as it cools, strengthening the bond between the two parts. The fusing process replaces the traditional method of sewing fabric parts and interlinings together for most fabric types. Why Fabric Fusing Machines are Indispensable - Fabric fusing machines are important in garment production for their ability to boost productivity. They provide a consistent and efficient means of bonding fabric, essential for industries ranging from fashion to automotive. These machines are specifically designed to apply the exact amount of heat and pressure needed to melt the adhesive resin, ensuring a strong bond without compromising the fabric quality. Operational Principles of Fabric Fusing Machines - Fabric fusing is most effective when temperature, pressure, and processing time are precisely controlled. To start with, the fabric is laid flat, and the machine is preheated to a specified temperature to avoid shrinkage. The resin-coated interlining is then placed onto the fabric, and the combination is fed into the fusing machine. Then, they are heated and pressed together under predetermined conditions before being set aside to cool, solidifying the adhesive. Advantages • Very reasonable for stack fabric utilizing • There is no plausibility of fabric shrinkage • The production of a continuous machine is high. • Quality of the fusing is good too. • For these reasons, it is mostly used in garments industries.

Send Message