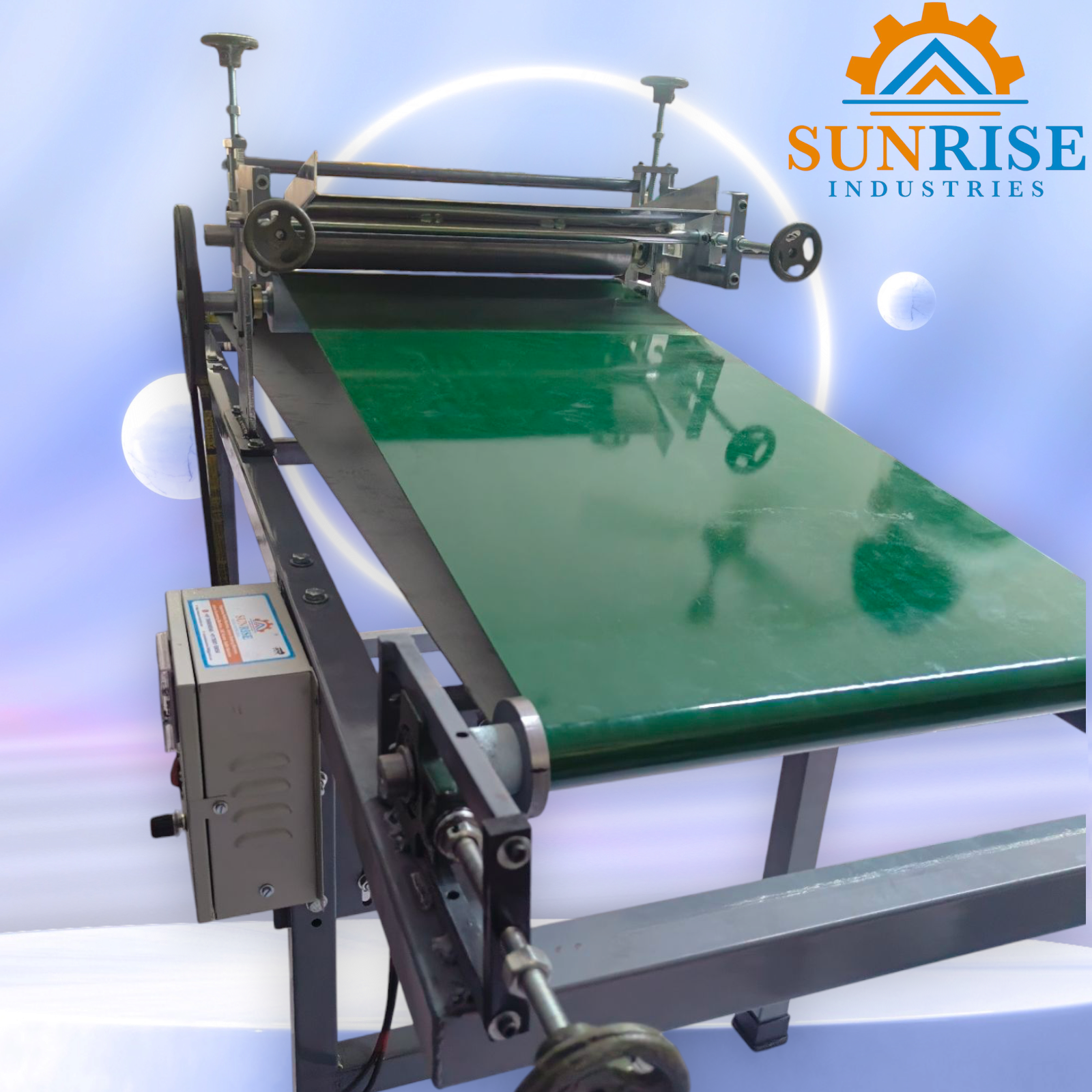

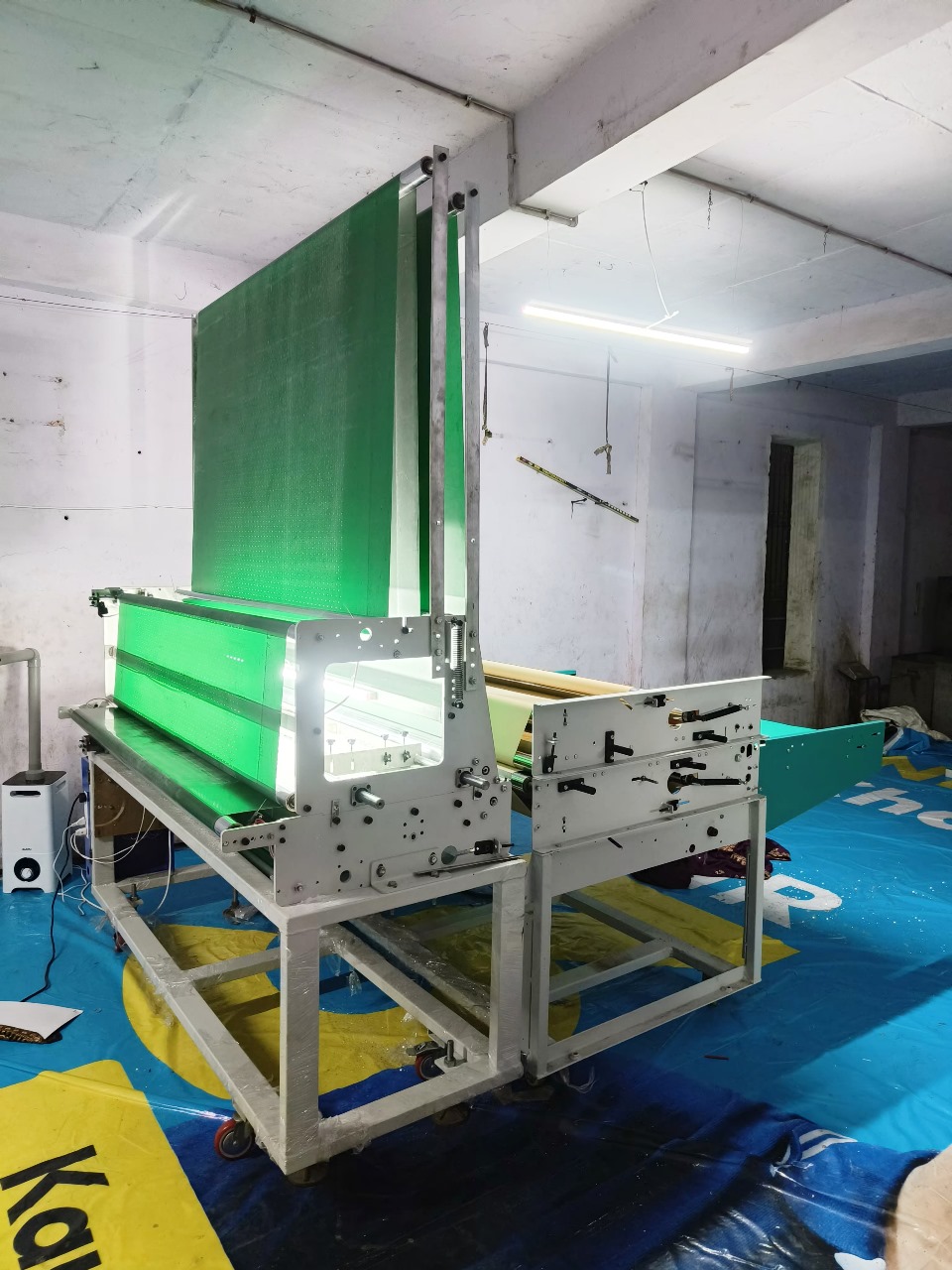

Definition A Two-Colour Automatic Rhinestone Transfer Machine is a specialized textile decoration device designed to automatically place and fix rhinestones of two different colors onto fabric or other materials using heat and precision alignment. It uses computer-controlled technology to read design patterns and accurately position rhinestones, enabling high-speed, consistent, and complex multi-color embellishments for garments. About Machine • Sunrise industries innovative new machine 2 colour automatic machine is transferring the 2 different types of stone colour like that golden, silver, blue etc. or 2 different types of stone like that 6ss,8ss,10ss etc. • The key function of a Two-Colour Automatic Rhinestone Transfer Machine is to automatically place and fix rhinestones of two different colors onto fabrics or materials with high precision and speed, primarily for garment and textile decoration. • This machine is also use to both different types of stone like that 6ss PP Stone and DMC Stone. • These machines are widely used in textile hubs city Surat, for high-volume, decorative garment production. • A Two-Colour Automatic Rhinestone Transfer Machine offers several advantages that make it a valuable asset for textile and garment decoration businesses. 🌟 Advantages of the Machine Dual-Color Efficiency Places two different rhinestone colors in one pass, reducing production time and enabling more complex designs. High-Speed Automation Automates rhinestone sorting, placement, and fixing, significantly increasing output and reducing manual labor. Precision and Consistency Uses computer-controlled systems to ensure accurate rhinestone placement, minimizing errors and improving product quality. Cost Savings Reduces waste through paperless transfer options and lowers labor costs by automating repetitive tasks. Versatile Design Capabilities Supports a wide range of patterns and materials, allowing for creative freedom in fashion, accessories, and home textiles. Durable Bonding Hot fix technology ensures rhinestones are securely attached, making finished products washable and long-lasting. User-Friendly Operation Many models feature touchscreens, design software compatibility, and easy maintenance, making them accessible even for small workshops. Scalable Production Ideal for both small-scale custom jobs and large-scale manufacturing, thanks to adjustable speed and design flexibility. Key Point of 2 Colour Paperless Machine Dual-color rhinestone placement – Automatically handles two rhinestone colors in one design pass Computerized design control – Uses digital files to guide precise rhinestone positioning Automatic sorting and fixing – Sorts, places, and heat-fixes rhinestones without manual intervention Hot fix technology – Bonds rhinestones securely to fabric using heat and adhesive Paperless transfer option – Some models eliminate the need for transfer paper High-speed production – Capable of processing hundreds of pieces per hour