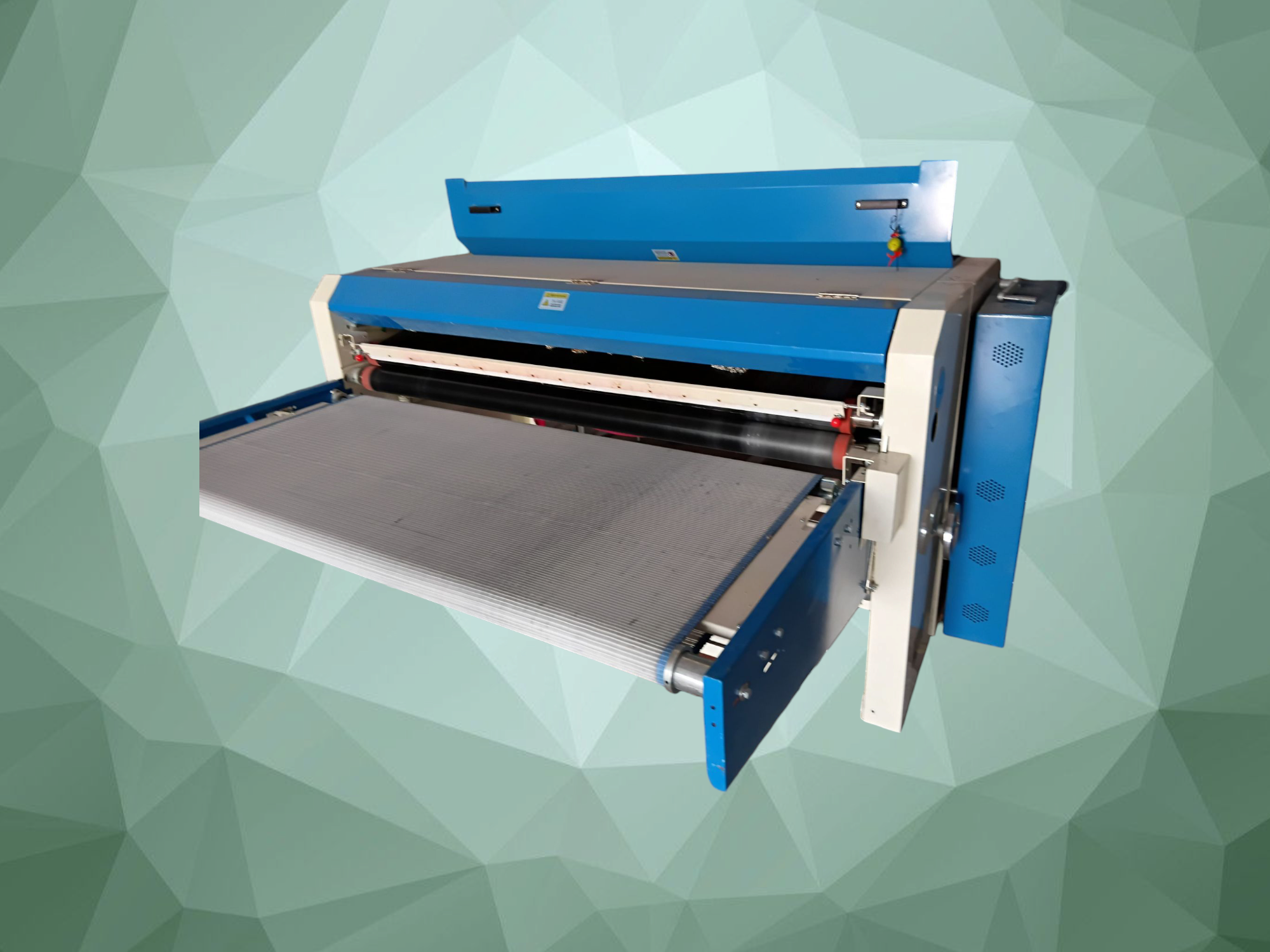

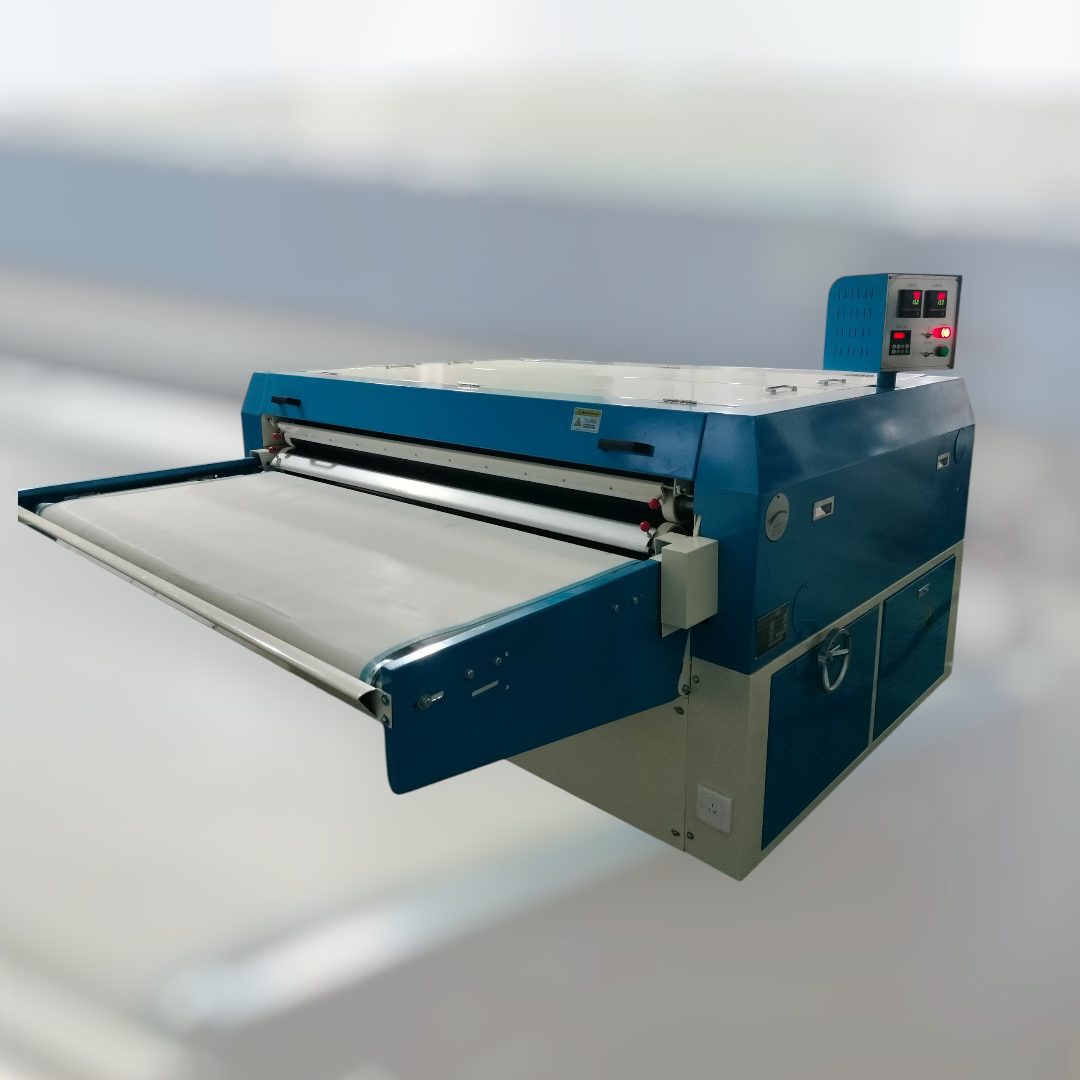

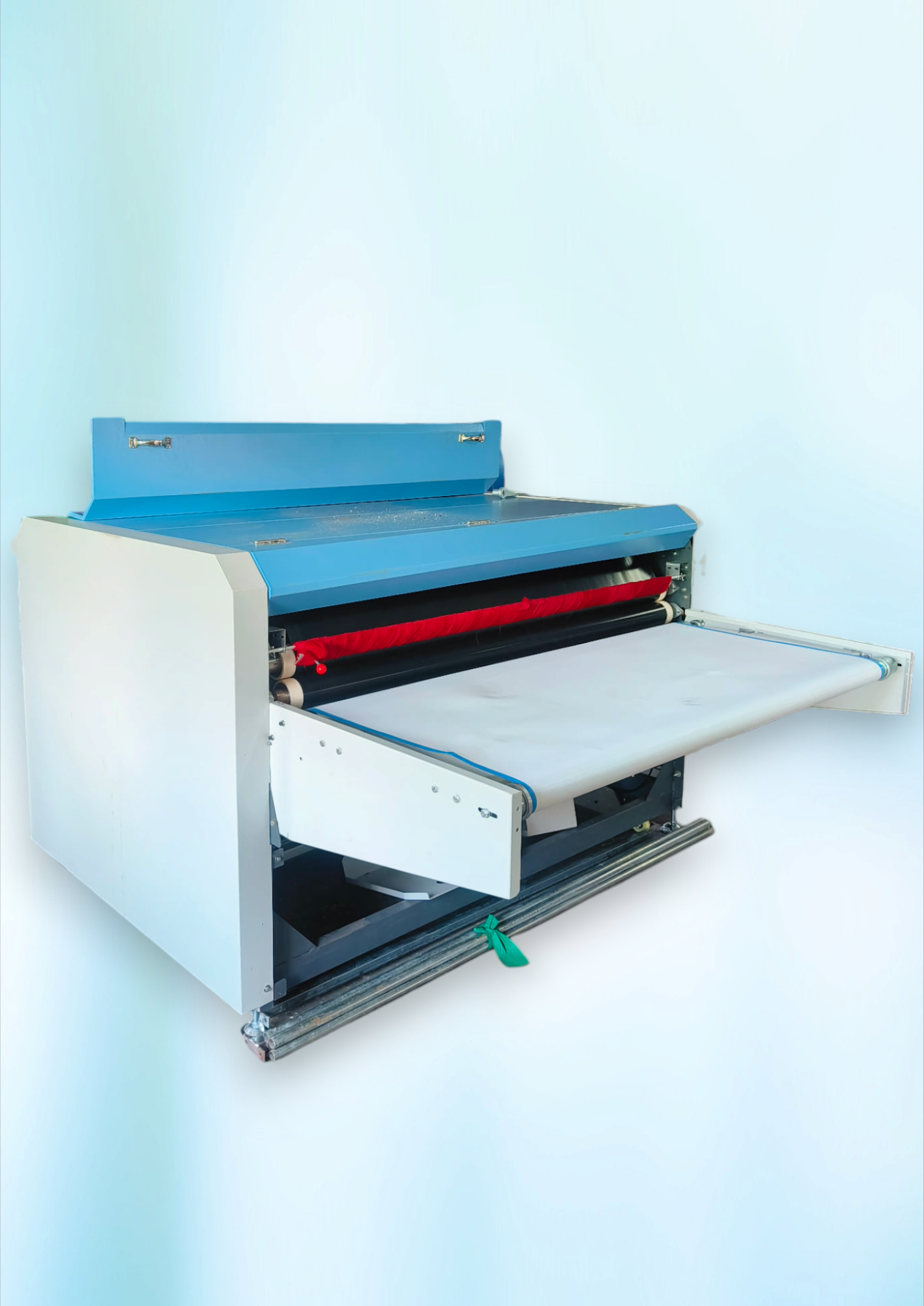

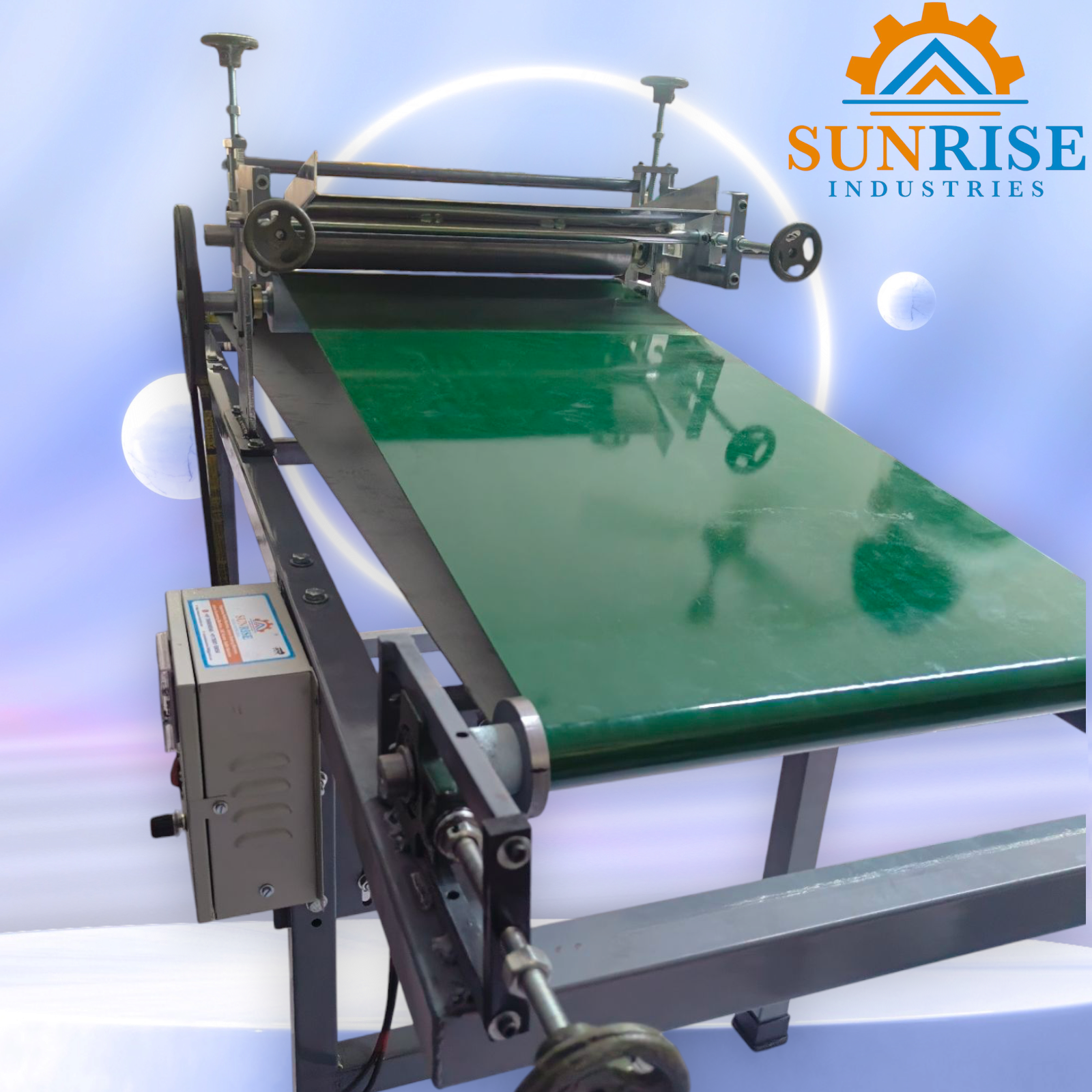

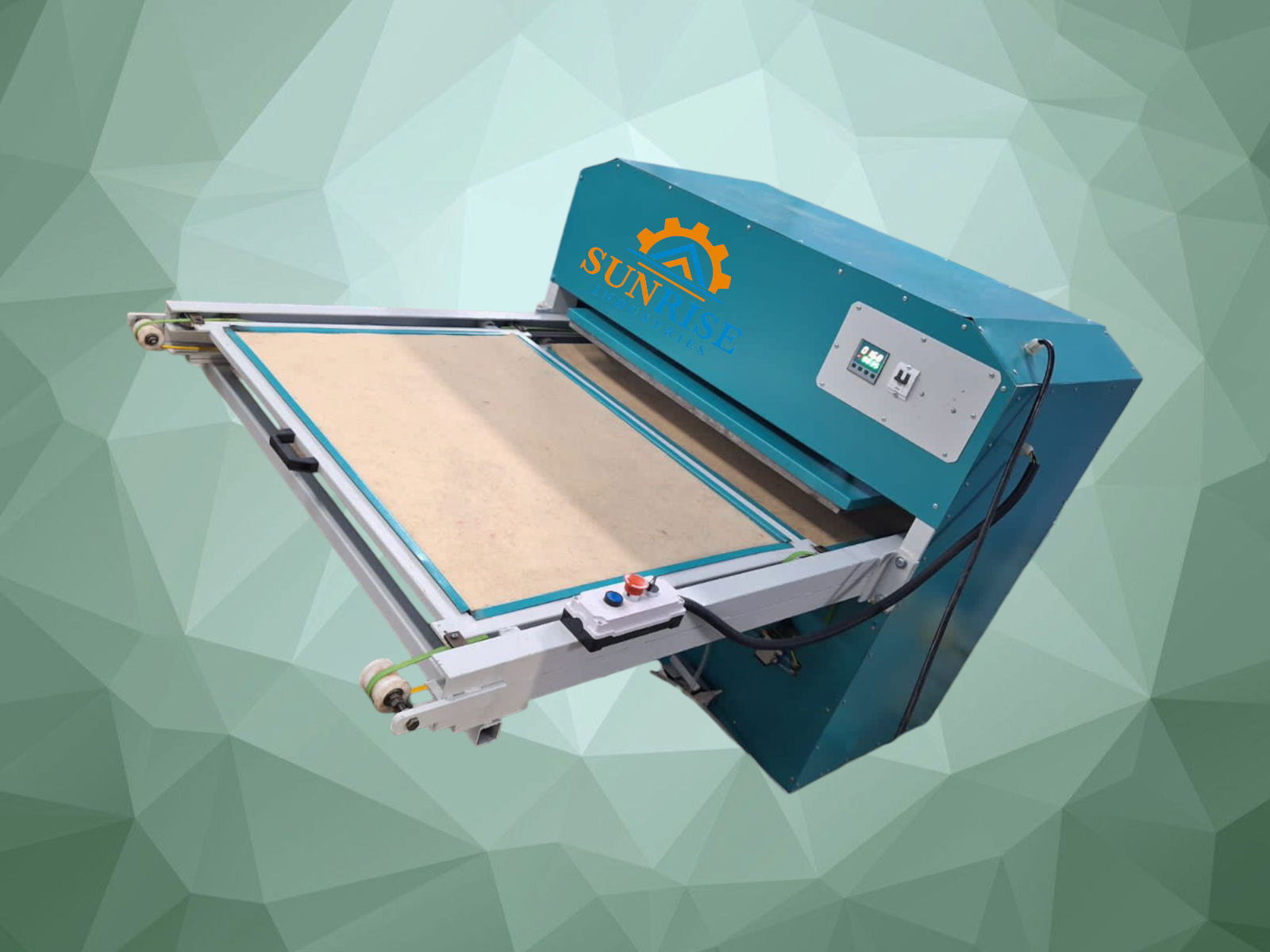

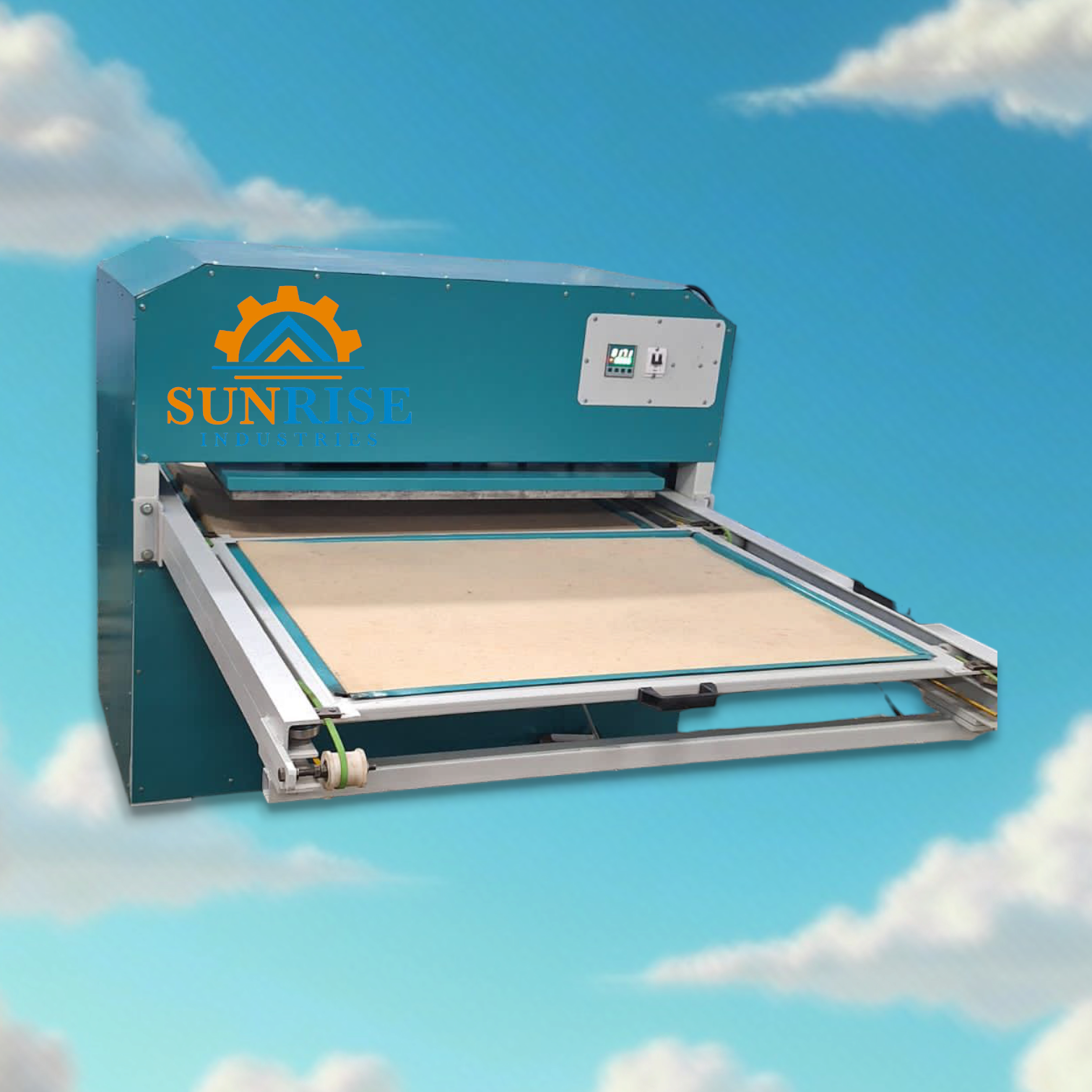

A fabric fusing machine is a type of industrial machine used to bond two or more layers of fabric together using heat, pressure, and sometimes adhesive. This process is known as “fusing“ and is typically used to attach a fusible material (such as interfacing, linings, or other components) to fabric. The purpose of fusing is to provide added strength, structure, or durability to the fabric, or to attach decorative elements. The fusing process involves the following steps: 1. **Heat**: The machine applies heat to activate the adhesive or fusible layer between fabrics. 2. **Pressure**: Pressure is applied to ensure the bond forms securely. 3. **Time**: The heat and pressure are applied for a specific time to ensure a solid bond. Fabric fusing machines come in various types, including: **Flatbed Fusing Machines**: Used for large sheets of fabric, typically found in garment manufacturing. - **Roller Fusing Machines**: Use rollers to apply pressure and heat, commonly used in high-volume operations. - **Vacuum Fusing Machines**: Use vacuum systems to ensure uniform pressure and are often used for delicate or intricate materials. These machines are often used in garment manufacturing, upholstery, and textile industries to ensure the proper adhesion of fabrics for various applications. What is Fabric Fusing Machine? During fabric fusing, an adhesive resin is applied to one side of the interlining and then bonded to another piece of fabric by applying heat and pressure. The resin solidifies as it cools, strengthening the bond between the two parts. The fusing process replaces the traditional method of sewing fabric parts and interlinings together for most fabric types. Why Fabric Fusing Machines are Indispensable Fabric fusing machines are important in garment production for their ability to boost productivity. They provide a consistent and efficient means of bonding fabric, essential for industries ranging from fashion to automotive. These machines are specifically designed to apply the exact amount of heat and pressure needed to melt the adhesive resin, ensuring a strong bond without compromising the fabric quality. Operational Principles of Fabric Fusing Machines Fabric fusing is most effective when temperature, pressure, and processing time are precisely controlled. To start with, the fabric is laid flat, and the machine is preheated to a specified temperature to avoid shrinkage. The resin-coated interlining is then placed onto the fabric, and the combination is fed into the fusing machine. Then, they are heated and pressed together under predetermined conditions before being set aside to cool, solidifying the adhesive.

Send Message