Fully Automatic Paper Plate Machine /

Rhinestone Fixing Machine

A paperless rhinestone transfer machine is a specialized

device used in the fashion and garment industry to apply rhinestones, studs,

and other embellishments onto fabric without the use of transfer paper.

These machines use advanced technology to pick and place

rhinestones precisely on a garment or fabric, facilitating the creation of

intricate and custom designs.

Key features typically include:

Automated Process: The machine automates the picking and

placing of rhinestones, increasing efficiency and precision compared to manual

methods.

Design Software Integration: They often come with or

support design software that allows users to create and upload custom patterns

and designs.

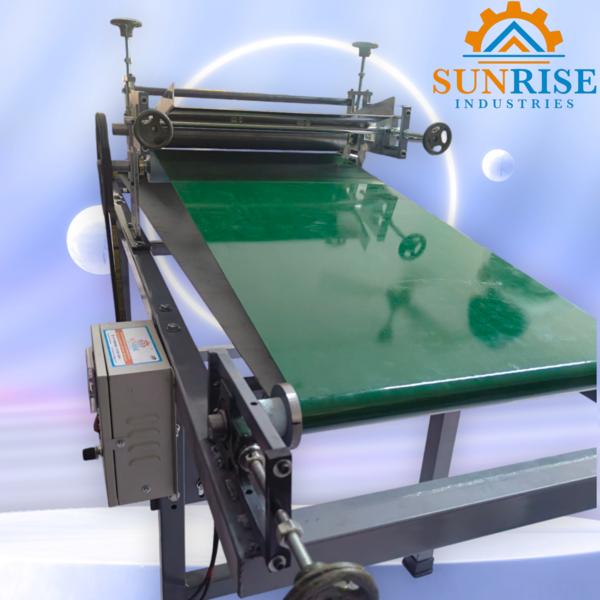

Single Roll to Roll Paperless Rhinestone Machine

- High Precision: These machines ensure accurate placement

of rhinestones, reducing errors and improving the quality of the final product.

- Speed: They can significantly speed up the production

process, making them ideal for high-volume orders.

- No Transfer Paper Needed: Traditional methods often

require transfer paper to place the rhinestones. These machines eliminate that

need, making the process more streamlined and less wasteful.

- Using such a machine, designers and manufacturers can

create detailed and consistent rhinestone designs on a variety of fabrics,

enhancing the aesthetic appeal of clothing, accessories, and other

textile products.

Paperless rhinestone transfer machines are mainly used in the textile and fashion industries to directly apply rhinestones onto fabrics without transfer paper. They improve efficiency, reduce costs, and enable high‑volume, precise, and customizable designs for garments like sarees, skirts, t‑shirts, and other fashion items.

🌟 Applications of Paperless Rhinestone Transfer Machines

1. Fashion & Apparel Industry

Sarees, skirts, and ethnic wear: Widely used in Indian fashion for embellishing saree pallus, lehengas, and dupattas with intricate rhinestone patterns.

Western wear: Adds sparkle to dresses, tops, jeans, jackets, and stage costumes.

Sportswear & dance costumes: Enhances performance outfits with durable, eye‑catching rhinestone designs.

2. Customization & Personalization

Enables bespoke fashion items with unique rhinestone patterns.

Popular for branded merchandise (e.g., logos, lettering, motifs on t‑shirts or caps).

- Supports small‑batch production for personalized gifts and boutique collections

3. Industrial & Commercial Production

Roll‑to‑roll fabric processing: Machines can handle up to 3,000–5,000 meters in 10 hours, making them ideal for bulk textile manufacturing

Automated precision: Ensures consistent rhinestone placement, reducing human error and labor costs.