🚨 Considerations

Cost: Around ₹1.4–1.5 lakh per unit.

Maintenance: Requires regular cleaning to avoid stone jamming.

Training: Operators must learn digital parameter settings for zero wastage.

Noise & vibration: Continuous shaking can be loud in workshop environments.

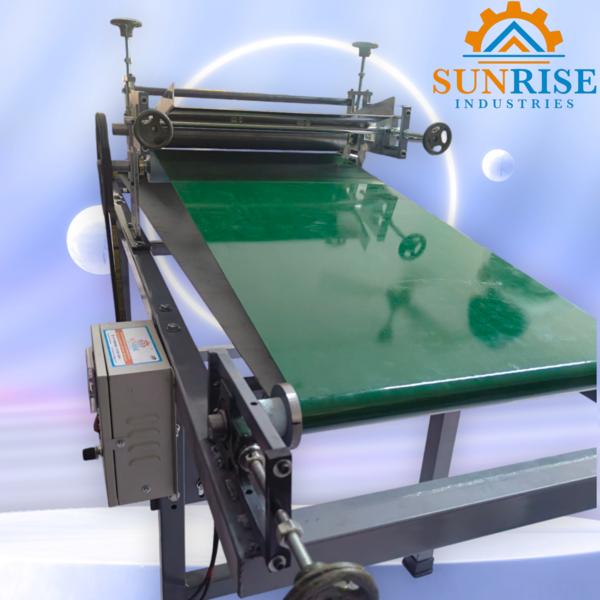

⚙️ What It Is

Purpose: Designed for the diamond/rhinestone textile industry, especially in Surat, to handle different sizes of round rhinestones, nailheads, and studs.

Function: Uses controlled shaking and vibration to separate, align, and feed stones into the next stage of garment embellishment.

Operation: Fully automatic, continuous shaking with adjustable speed and tilt angles for precision.

📌 Applications

Textile embellishment: Sarees, lehengas, blouses, and western garments decorated with rhinestones.

Accessories: Bangles, belts, bags, and shoes with stonework.

Industrial production: High‑volume processing of stones for garment factories.

Customization: Supports boutique fashion houses for unique designs.

Textile embellishment: Sarees, lehengas, blouses, and western garments decorated with rhinestones.

Accessories: Bangles, belts, bags, and shoes with stonework.

Industrial production: High‑volume processing of stones for garment factories.

Customization: Supports boutique fashion houses for unique designs.

🌟 Key Features

| Feature | Description |

|---|---|

| Automatic operation | PLC & touch‑screen HMI based system for easy control |

| Capacity | Handles multiple sizes of stones (SS10–SS20 and beyond) |

| Speed range | Up to 15,000 cycles, ensuring high production speed |

| Safety | Dual start pushes buttons and microcomputer controller for operator safety |

| Durability | Heavy‑duty alloy steel build, portable design, ~150–175 kg weight |

| Power | Runs on 220–230V, ~1.5 kW power consumption. |