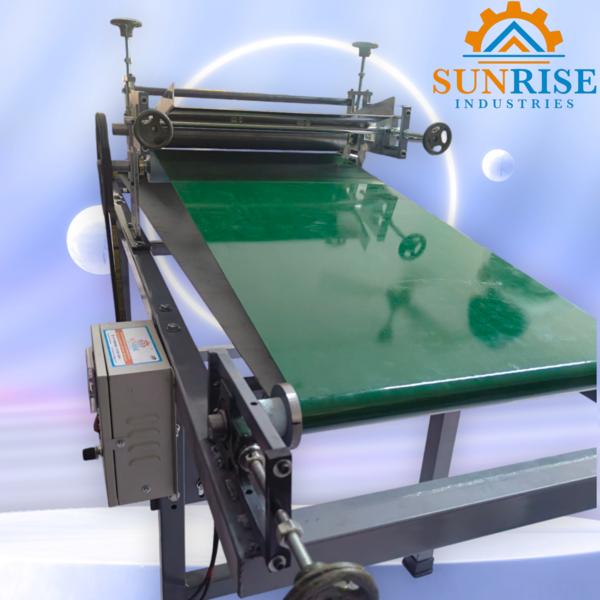

Two Colour Automatic Rhinestone Transfer

Machine

Definition

A Two-Colour Automatic Rhinestone Transfer

Machine is a specialized textile decoration device designed to automatically

place and fix rhinestones of two different colors onto fabric or other

materials using heat and precision alignment. It uses computer-controlled technology

to read design patterns and accurately position rhinestones, enabling

high-speed, consistent, and complex multi-color embellishments for garments.

About Machine

· Sunrise

industries innovative new machine 2 colour automatic machine is transferring

the 2 different types of stone colour like that golden, silver, blue etc. or 2

different types of stone like that 6ss,8ss,10ss etc.

· The

key function of a Two-Colour Automatic Rhinestone Transfer Machine is to

automatically place and fix rhinestones of two different colors onto fabrics or

materials with high precision and speed, primarily for garment and textile

decoration.

· This

machine is also use to both different types of stone like that 6ss PP Stone and

DMC Stone.

· These

machines are widely used in textile hubs city Surat, for high-volume,

decorative garment production.

· A Two-Colour Automatic Rhinestone Transfer Machine offers several advantages that make it a valuable asset for textile and garment decoration businesses.

Features to Look For

- Two

Colour Capability: Allows simultaneous placement of

two rhinestone colors, improving design flexibility and production speed.

- Automatic

Transfer System: Reduces manual labor and increases

precision.

- Hot

Fix Functionality: Ensures rhinestones are securely

bonded to fabric using heat.

- Brush/Shaking

Mechanism: Helps align rhinestones before transfer.

🔧

Primary Functions

Dual-Color Rhinestone Placement

Ø Automatically

selects and places rhinestones of two distinct colors in a single design

pass.

Ø Enhances

design complexity and visual appeal without manual sorting.

Automated Transfer Process

Ø Uses a

computer-controlled system to position rhinestones based on preloaded

design files.

Ø Eliminates

manual alignment, reducing labor and error.

Hot Fix Technology

Ø Applies

heat to secure rhinestones onto fabric using adhesive backing.

Ø Ensures

strong bonding suitable for washing and wear.

Paperless Transfer Option

Ø Some

models offer paperless rhinestone transfer, reducing material waste and

cost

High-Speed Production

Ø Capable

of processing up 150-200 pieces per hour depending on the model.

Ø Ideal for mass production in apparel factories.

Design Versatility

Ø Supports

a wide range of patterns, fonts, and motifs.

Ø Compatible

with various fabrics including cotton, polyester, denim, and blends.

Precision and Consistency

Ø Uses servo

motors and sensors to maintain accurate placement.

Ø Reduces

defects and ensures uniform quality across batches