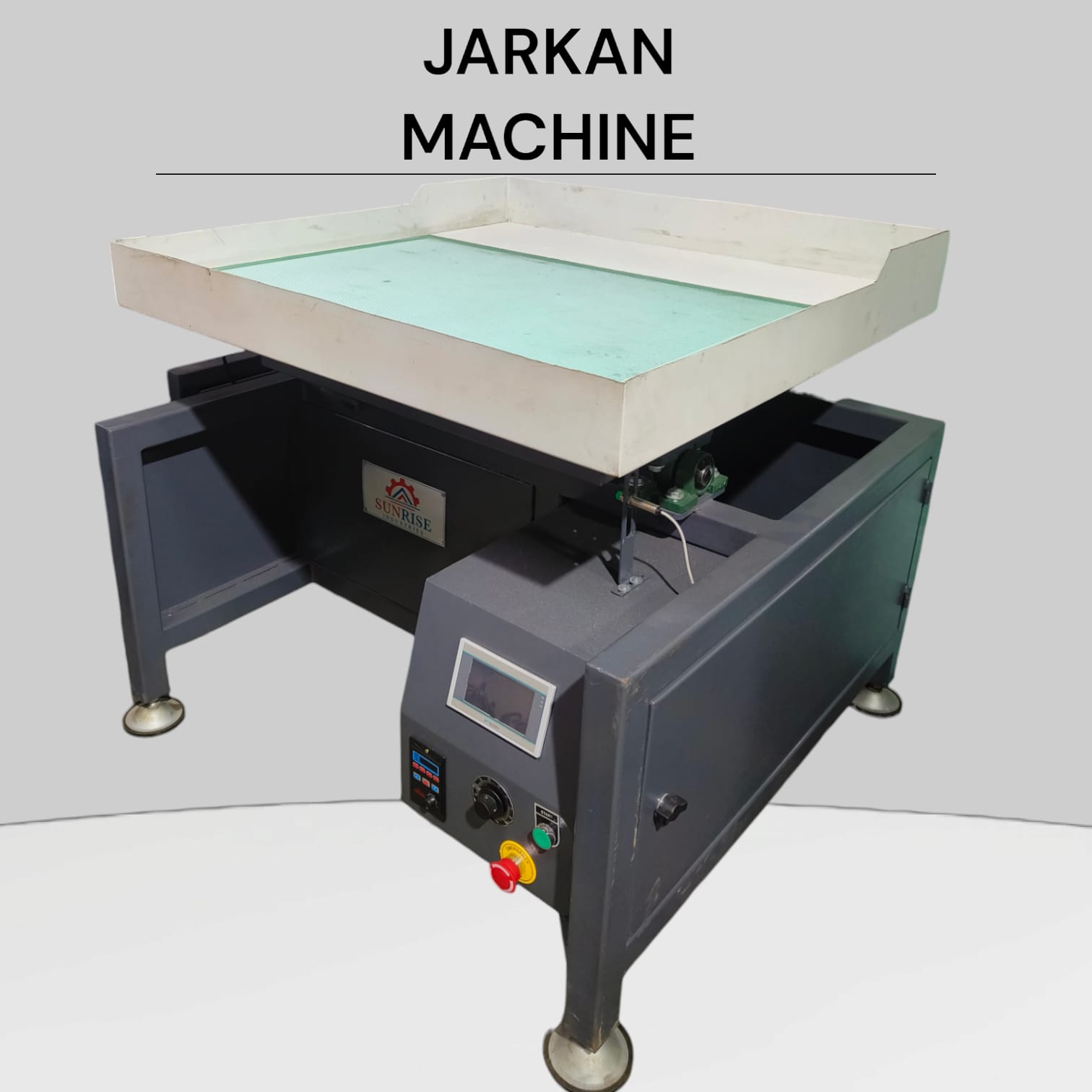

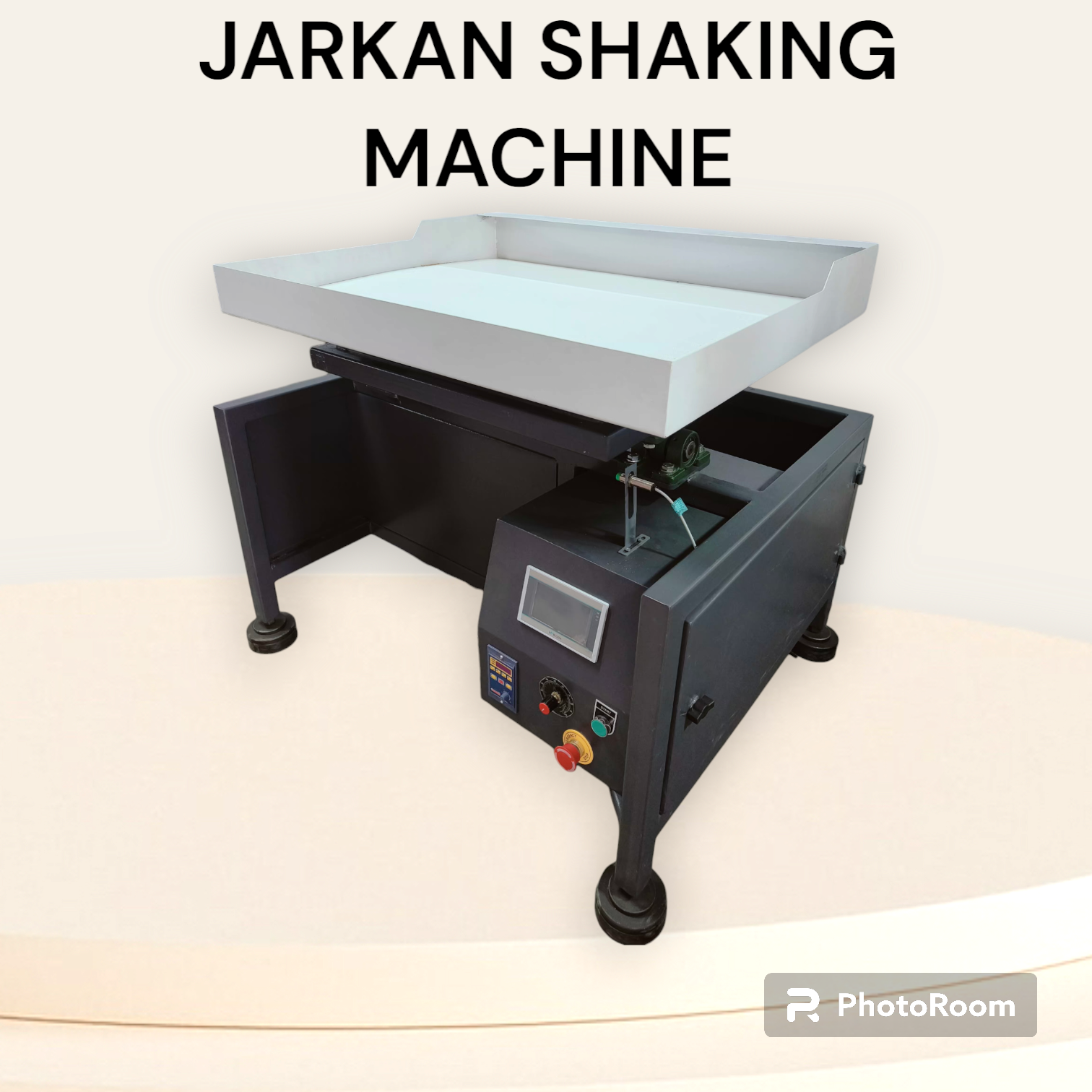

The Jarkan Machine, also known as the Jarkan Shaking Machine, is a specialized device used primarily in the textile industry. It is designed to handle different sizes of round rhinestones, Jarkan stones, various nail heads, and abnormal studs. The machine can automatically rise and decline, and it efficiently collects stones, which saves both time and labor. - The Jarkan Shaking Machine is available in both manual and automatic versions, and it includes features such as an emergency stop facility for enhanced safety. It operates with a voltage of 220 V and typically has a capacity of producing 4-5 pieces per minute. - This machine is widely used for creating designs on sarees, dresses, bangles, footwear, and lace, making it an essential tool for textile and garment manufacturing processes. JARKAN Machine Technical Data The Jarkan Shaking Machine has several technical specifications tailored for the textile industry, making it efficient and versatile for various applications. Here are the key technical details: -Voltage: 220 V - Power Consumption: Typically, around 1 kW/h, varying slightly depending on the model - Production Capacity: Approximately 4-5 pieces per minute for some models. Up to 500 sheets per day for others. - Weight: Around 160 kg, depending on the specific machine configuration. - Phase: Single-phase. - Working Size: Common sizes include 16x24 inches, 18x30 inches, 20x30 inches, 16x16 inches, 24x24 inches and 24x32 inches - Machine Material: Usually made of mild steel - Frequency: Ranges between 40 Hz and 50 Hz Additional features: - Automatic Operation - Emergency Stop Facility: Enhances safety during operation. - User-Friendly Controls: Often includes a microcomputer controller with an LCD display. These specifications highlight the machine's capability to handle various sizes and types of stones, making it suitable for detailed and high-volume textile applications. Jarkan Shaking Machine is suitable for different sizes of round rhinestones, various nailheads, abnormal studs etc. It can automatically rise and decline, automatically collect stones, saving time and labor. The Jarkan Shaking Machine is designed for creating intricate designs using round rhinestones, nailheads, and abnormal studs. Here are some key features: • Suitable for Different Sizes: The machine works with various sizes of round rhinestones, Jarkan stones, and nailheads. • Automatic Operation: It can automatically rise and decline, as well as collect stones, saving time and labor. • Manual and Automatic Options: You can choose between manual and automatic modes. • Emergency Stop Facility: An emergency stop feature ensures safety during operation. The Jarkan Shaking Machine is commonly used in the textile industry for embellishing fabrics and garments. Here are some applications: 1. Sarees and Lehengas: Designers use the machine to create intricate patterns and motifs on sarees and lehengas, enhancing their overall appeal. 2. Dresses and Gowns: The machine adds sparkle to dresses and gowns by attaching rhinestones, nail heads, or Jarkan stones in artistic arrangements. 3. Footwear: Shoe manufacturers use the machine to decorate footwear, especially bridal shoes and party wear. Panel details in JARKAN shaking Machine The control panel of the Jarkan Shaking Machine is designed to facilitate easy and precise operation. Here are the main features and details commonly found in the machine's control panel: Microcomputer Controller: - The machine often includes a microcomputer controller which enhances the precision and control over the shaking and stone placement processes. - This controller typically comes with an LCD display for easy monitoring and adjustment of settings. User Interface: - The panel features a user-friendly interface that allows operators to input design patterns, adjust machine settings, and monitor the operational status. - Buttons or touch controls are usually available for starting, stopping, and adjusting the machine's functions. Emergency Stop Facility: - An emergency stop button is a critical safety feature included on the control panel. This allows operators to immediately halt the machine in case of any issues or emergencies. Automation Controls: - The control panel provides options for switching between manual and automatic modes, giving flexibility in operation depending on the specific task requirements. - Automated systems within the panel handle the rise and decline functions, as well as the collection of stones, ensuring efficient and consistent performance. Power and Electrical Controls: - The panel includes switches and indicators for power supply, ensuring the machine is properly powered and operational. - Voltage and frequency settings are managed through the panel to ensure compatibility with the industrial power supply.