The key function of a gumming machine is to apply a uniform layer of adhesive (gum) to materials such as:

-

Rhinestones or Jarkan stones (in the textile industry),

-

Labels, paper, or film (in packaging or printing),

-

Stickers and tapes (in manufacturing).

🏭 Examples by Industry

🔹 Textile & Garment Industry

-

Gums hot-fix rhinestones (Jarkan stones) before they go onto sarees, dresses, or accessories.

🧩 Core Functions of a Gumming Machine

| Function | Description |

|---|---|

| 🧴 Adhesive Application | Applies a precise and even coat of gum (glue) to the back surface of items. |

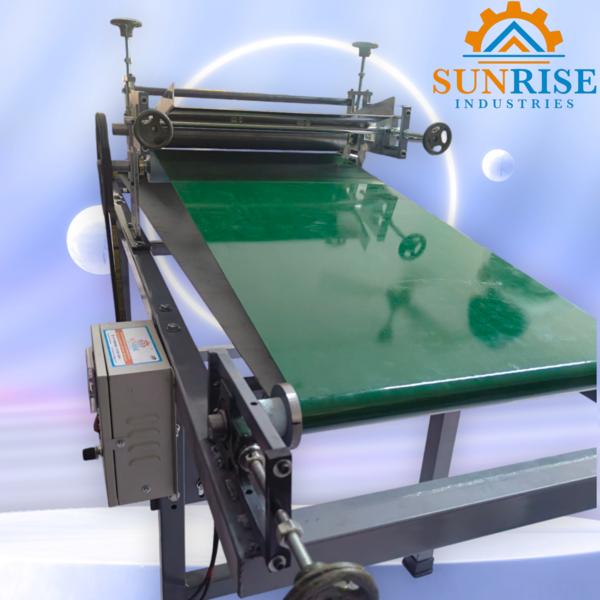

| ⚙️ Automated Rolling | Uses rollers (silicon or metal) to spread gum as items move through the machine. |

| 🎛 Controlled Feed & Speed | Adjustable conveyor speed and gum flow for different material types and thicknesses. |

| 🧼 Minimized Waste | Applies only the needed amount of gum, reducing overuse or mess. |

| 🧵 Preparation for Bonding | Makes materials (like stones or paper) ready to be attached to fabric, plastic, etc. |