65d485c33a5595d821201a9c

SUNRISEINDUSTRIES2CCB

65d485c33a5595d821201a9c

SUNRISEINDUSTRIES2CCB

products

68179d65be22ee500d53ff54

Hotfix Machine Manufacturer

+917600169054

Chat with us on WhatsApp

×

Thank you for writing to us. One of our executive will reach back to you through your submitted medium. In case there’s an urgency, feel free to connect over WhatsApp for faster response.

Chat with us on whatsapp Prefer calling? Dial +9108043694786 (International callers) or 08043694786 (Indian callers).

18

https://www.sunriseinds.com/latest-update/jarkan-gumming-machine/131

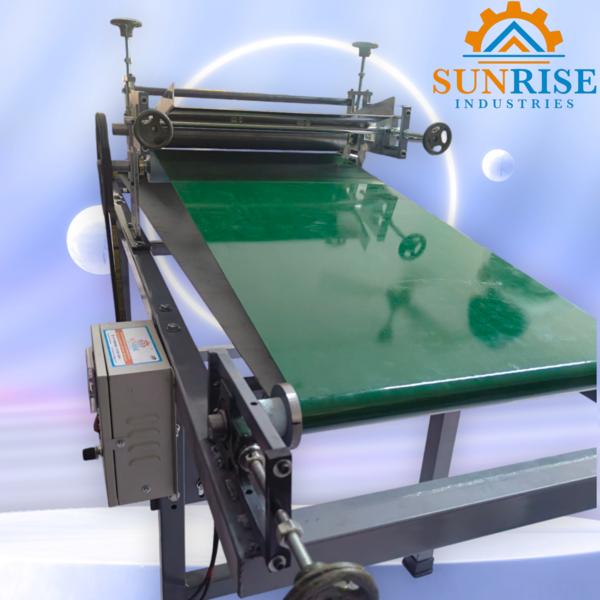

✅ Advantages of a Jarkan Gumming Machine

Advantage Details 🕒 Time-Saving Automates the adhesive application process, dramatically reducing manual labor and time. 🎯 Precision & Consistency Applies a uniform layer of gum on each stone, ensuring better bonding and final results. 📈 High Productivity Can process hundreds of stones or templates per hour — ideal for large-scale production. 🧵 Improved Finish Quality Leads to cleaner, more professional-looking designs once stones are heat-pressed onto fabric. 🛠 Less Manual Error Reduces the risk of over-gumming or under-gumming, ensuring higher success rates in transfer. 🔧 Adjustable Settings Tray height, roller pressure, gum flow, and conveyor speed can be customized as per stone type. 💸 Cost-Efficient Long Term Cuts down labor costs and gum wastage, saving money over time despite higher upfront investment. ⚙️ Integrates with Other Machines Often used in tandem with shaking and hot-fix machines in automated production lines. ♻️ Reduced Gum Wastage Controlled gum delivery minimizes excess usage, which is common in manual processes. 🧼 Clean & Safe Operation Many models come with easy-to-clean rollers , spill-prevention trays, and safety covers.

Keywords

High productivity stone bonding

Automated adhesive application process

Jarkan Gumming Machine advantages

À5, city industry, Udhana GIDC, Citi Industrial Estate, Udhna Udhyog Nagar, Udhana, Surat, Gujarat 394210, India

394210

Surat

India

08043694786

Hotfix Machine Manufacturer

https://www.sunriseinds.com

0

6792228e101b6a6540e12c77 65d485c33a5595d821201a9c