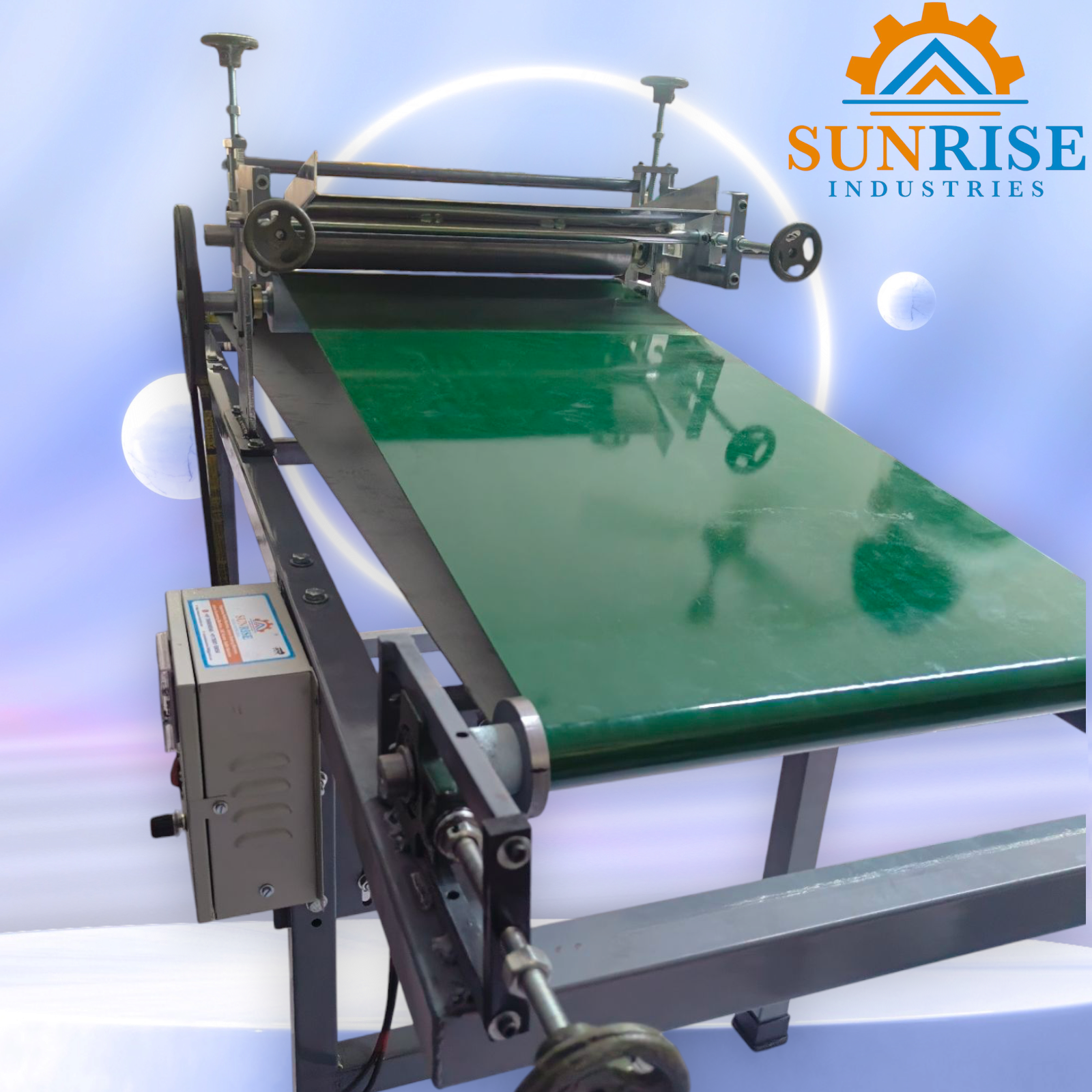

LIVE JARKAN DIAMOND GUMMING MACHINE The JARKAN diamond gumming machine is a specialized piece of equipment used in the application of gum to rhinestones and similar decorative elements, particularly for use in textiles and garments. This machine facilitates the precise and efficient placement of gum on various sizes and types of stones, including hot fix Jarkan and nail head stones. Key features of the JARKAN diamond gumming machine include: Adjustable Speed and Conveyor: - Equipped with a strong conveyor belt and a motor with adjustable speed for optimized performance. Material Compatibility: - The machine features silicon and mild steel rolls, making it versatile for different gumming needs. Ease of Use: - It comes with adjustable gumming trays and an emergency stop facility for safety and ease of operation. Automation: - It can automatically rise and decline, collect stones, and perform other automated functions, saving time and labor. These features make it particularly useful for industries involved in garment embellishment, such as saree and dress manufacturing, where precision and efficiency are critical. Process of Gumming Machine The process of using a gumming machine involves several steps to ensure the proper application of gum to stones or other embellishments for textiles. Here's an outline of the typical process: Preparation: - Material Setup: Place the rhinestones or other decorative elements in the designated input tray. - Machine Setup: Adjust the machine settings according to the type and size of the stones, and the specific gumming requirements. Feeding: - Conveyor Operation: The conveyor belt moves the stones into the gumming area. The speed and alignment can be adjusted to ensure consistent application. Gum Application: - Roll Application: The machine uses silicon and mild steel rolls to apply a uniform layer of gum to the stones as they pass through. - Adjustable Tray: The gumming tray can be adjusted to control the amount of gum applied, ensuring the stones receive the right amount of adhesive. - Drying Mechanism: Some machines may have a built-in drying mechanism to ensure the gum sets properly before the stones are used. This can involve heat application or air drying. Collection of Gum: - Output Tray: After gumming and drying, the Gum are collected in an output tray or conveyor for further processing or packaging. Quality Control: - Inspection: Stones are inspected to ensure they have been properly gummed and that there are no defects. Maintenance: - Cleaning: Regular cleaning of the machine, particularly the gumming components, to prevent buildup and ensure consistent performance. - Adjustment and Calibration: Periodic checks and adjustments to maintain accuracy and efficiency. This process ensures that the stones are properly prepared for application to textiles, such as sarees, dresses, and other garments, enhancing their aesthetic appeal and durability.

Send Message