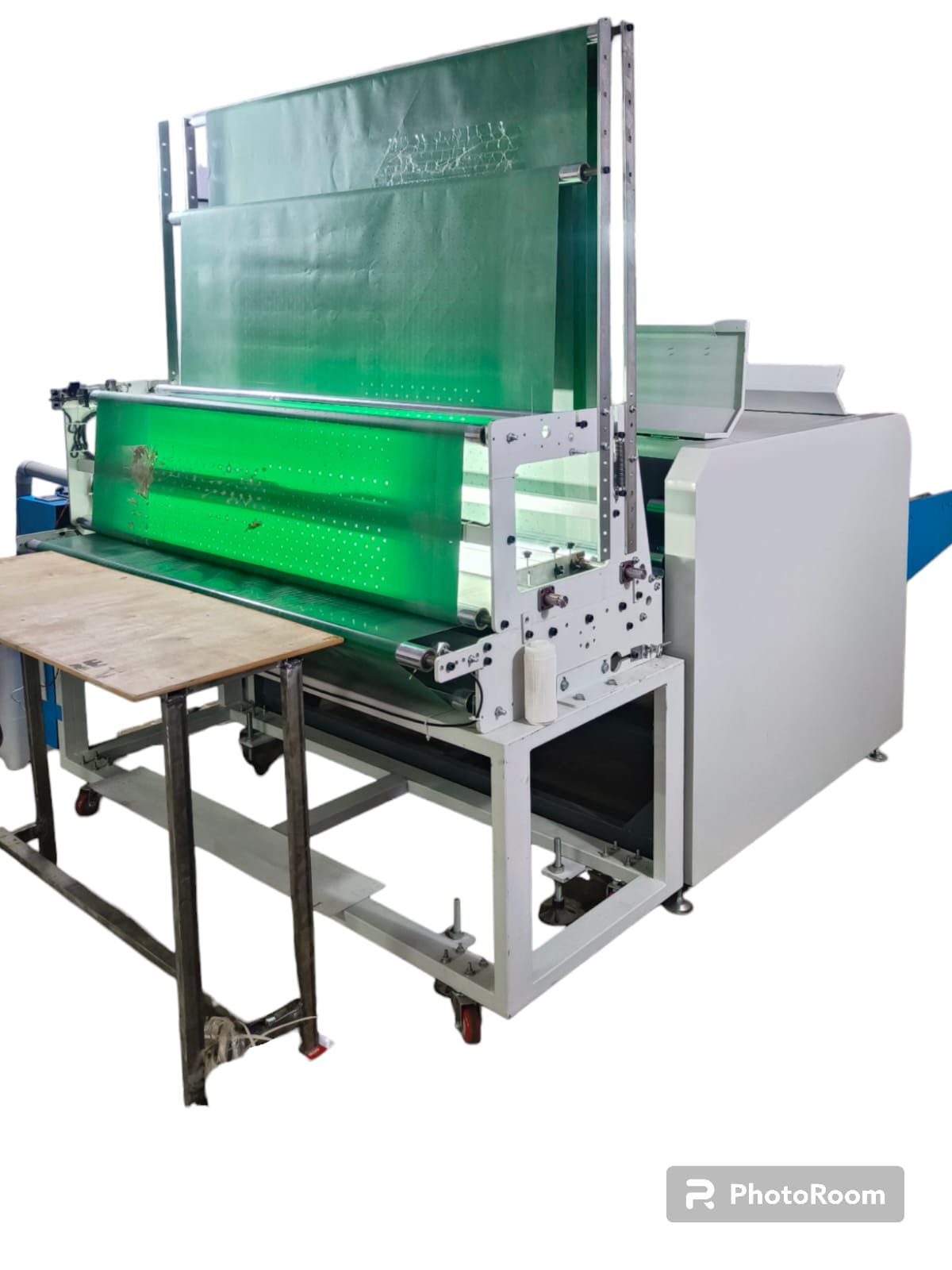

The machine's main purpose is to create intricate rhinestone designs on various materials. It uses hotfix rhinestones, which have a heat-activated adhesive on the back that securely attaches the stones to the fabric when heated. - We ensure our provided Jarkan Shaking Machine / Rhinestone Shaking Machine always remains the best in quality and also, we give best delivery for customer in Surat. we give Machine are completely reliable because Sunrise industries is extremely experienced and offers good quality services. - With expert knowledge of the hotfix sector and client expectation work mechanism, Sunrise industries ensure the best and most effective nail stone Shaking Machine / Rhinestone Shaking Machine for its customers. And, also with advanced features, satisfying all the users with their desired results. - If you're in the market for a versatile, best quality machine, dependable shaking machine for your rhinestone designs, the sunrise industries Rhinestone Shaking Machine from Jarkan is an excellent choice. With its powerful motor, adjustable vibration settings, good quality bearing etc. this machine can help you achieve precise and dazzling rhinestone designs on a variety of materials with ease. - Automatic paperless Machine can transfer hotfix stone (RHINESTONE) directly on saree without using hotfix paper. - A fusing machine is a crucial piece of equipment in the textile and apparel industry. It’s used to bond Diamond and fabrics together using heat and pressure. - It's a special purpose machine for the rhinestone transfer to fabric. Suitable for all kind of fabric. Adopted mechanical connection unit form belt controlling, pressure regulating, conveyer, automatic stripping off etc. It is ideal choice for all kind of clothing factory with advantages of reliability, uniform heating, strong fusing, simple unloading, easy belt replacing and maintenance. - These machines are essential for transferring rhinestones or other decorative elements onto fabric. They ensure a strong bond between the embellishments and the textile material. Fusing Machine Key Feature - Power Consumption: 15 KW - Max Temperature: 200°C - Suitable for all kinds of fabric - Automation Grade: Automatic

Send Message