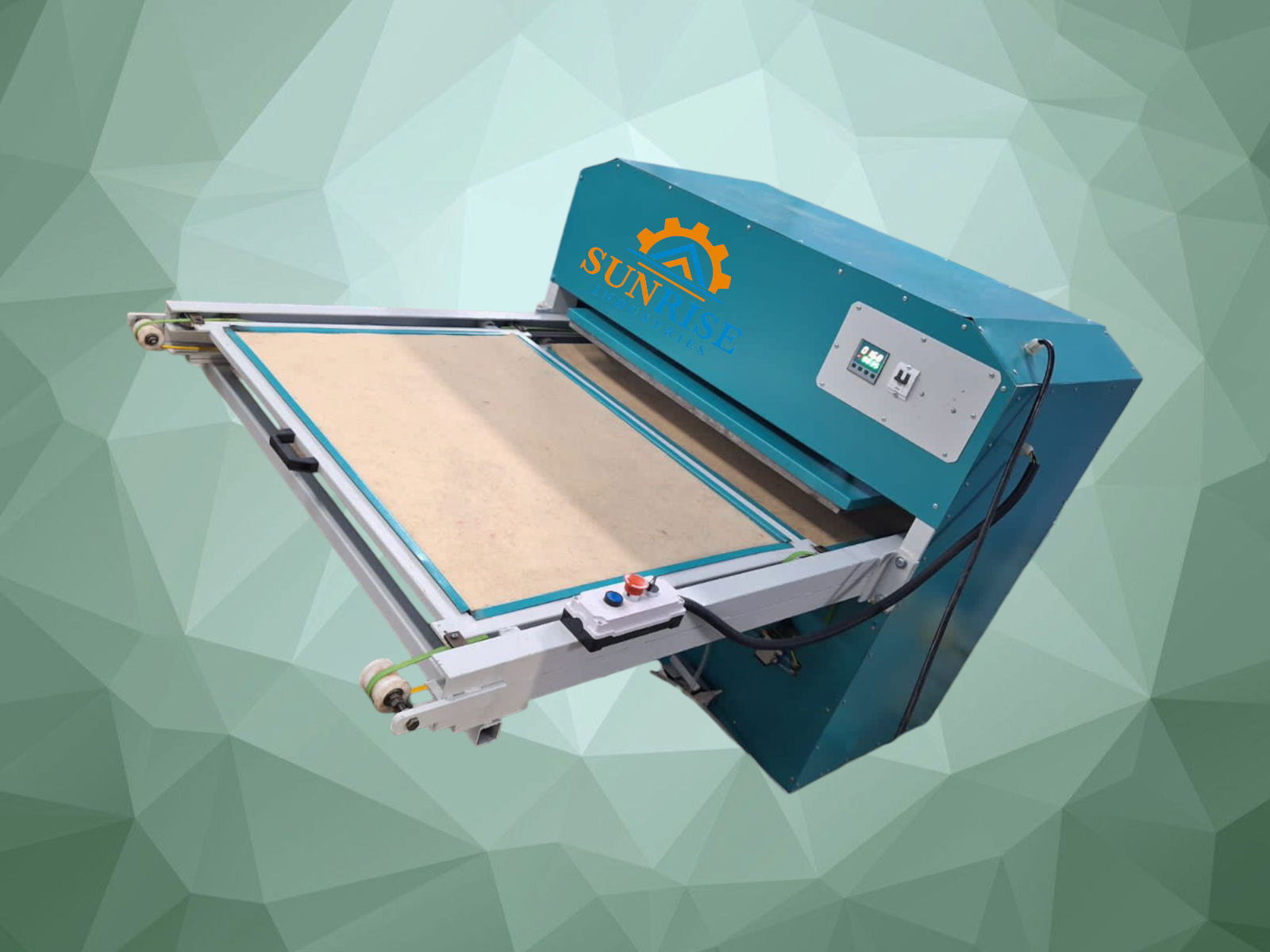

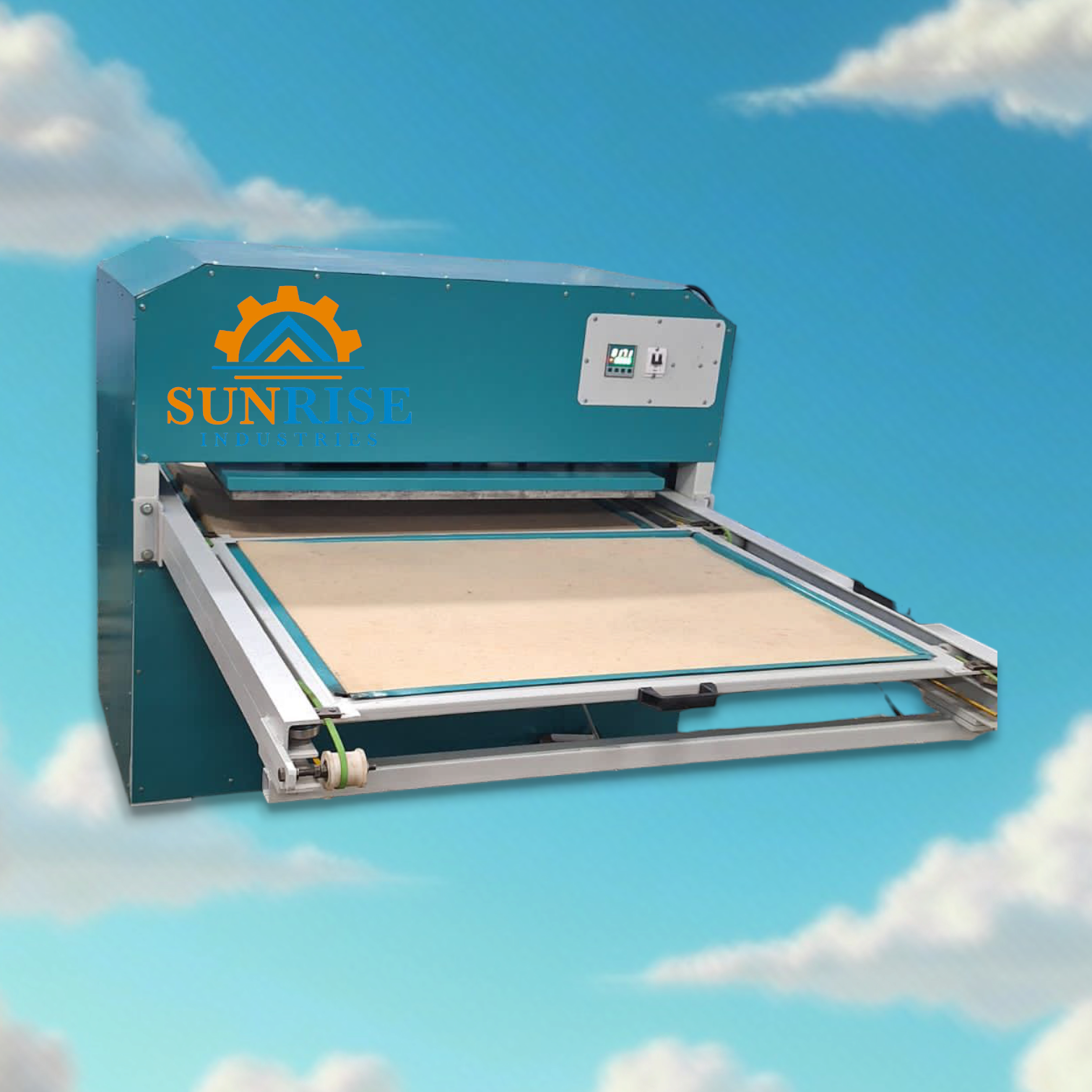

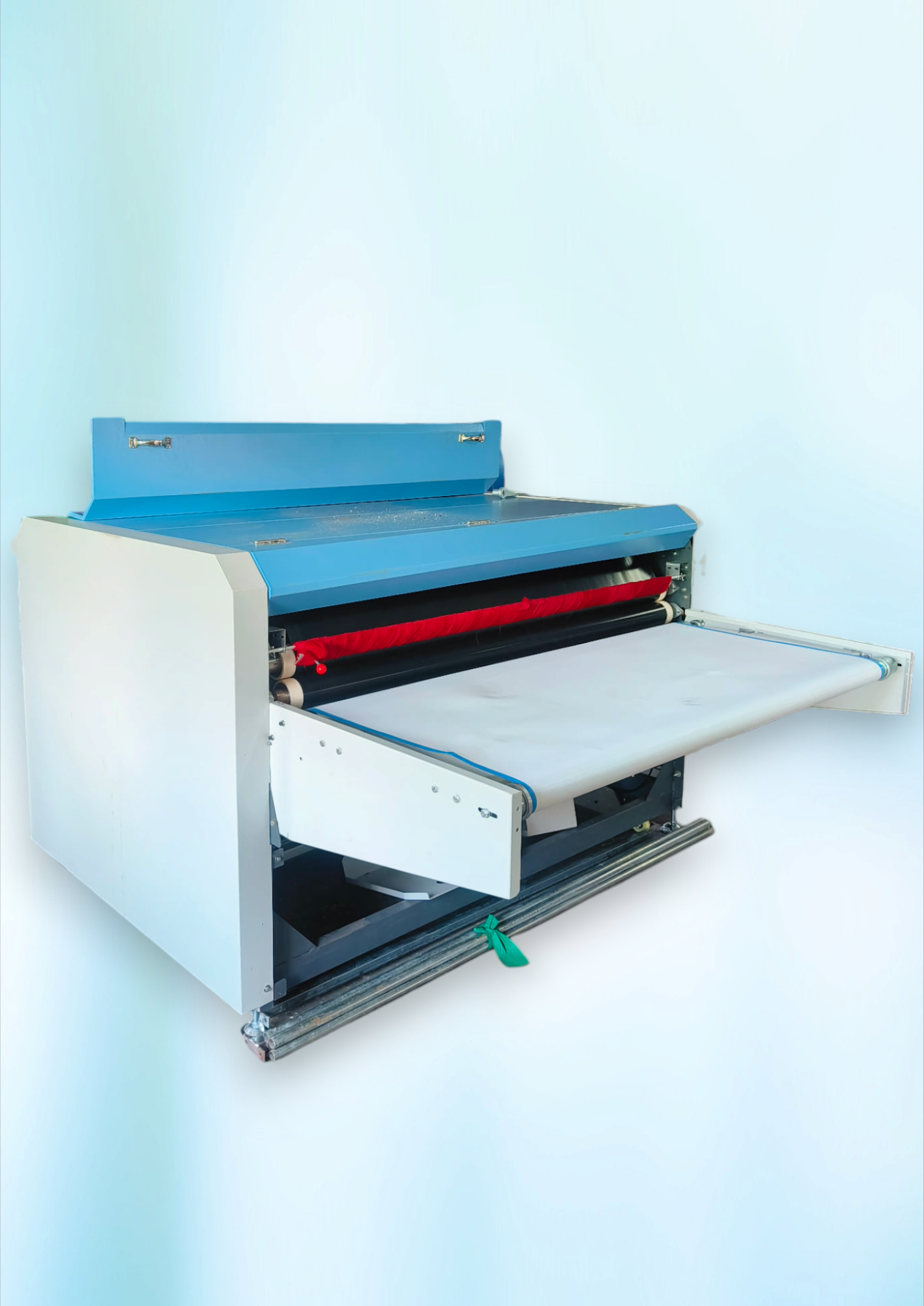

SUBLIMATION T-SHIRT PRINTING MACHINE A sublimation T-shirt printing machine is a high-tech device used to transfer designs onto T-shirts and other materials. Here's a quick rundown of how it works and its main functions: Design Creation: You start by creating a design using sublimation-compatible software and printing it onto special sublimation transfer paper using sublimation inks. Positioning and Heating: The printed transfer paper is placed on the T-shirt, and a heat press is used to apply high heat and pressure. Dye Transformation: The heat turns the solid ink into a gas, which penetrates the fabric's fibers and bonds with them. Final Result: Once cooled, the ink returns to a solid state, leaving a vibrant, long-lasting design that’s part of the fabric itself. Sublimation printing is known for producing rich, full-color designs with incredible detail and sharpness. The prints are highly durable and won't crack, peel, or fade over time, even with repeated washing. Functionality: 1. Design Preparation: o The process begins with creating a digital design using graphic design software. This design is then printed onto special sublimation transfer paper using sublimation inks. 2. Heat Transfer: o The printed transfer paper is placed onto the T-shirt or fabric. A heat press machine is used to apply high heat and pressure to the transfer paper and fabric. 3. Sublimation Process: o Under the high heat and pressure, the sublimation inks on the transfer paper turn into gas. This gas permeates the fabric fibers and solidifies, embedding the design into the fabric. 4. Permanent Bond: o The result is a permanent, vibrant print that becomes part of the fabric. The design won't crack, fade, or peel, ensuring long-lasting quality.

Send Message