- High Efficiency: Continuous processing of fabric rolls

significantly speeds up production compared to batch processing methods.

- Reduced Waste: Eliminates the need for transfer paper,

reducing material costs and environmental impact.

- Precision and Consistency: Ensures accurate and consistent

placement of rhinestones across long lengths of fabric.

- Customization and Complexity: Supports intricate and varied

designs, allowing for customization on a large scale.

- Labor Savings: Automation reduces the need for manual labor, lowering operational costs.

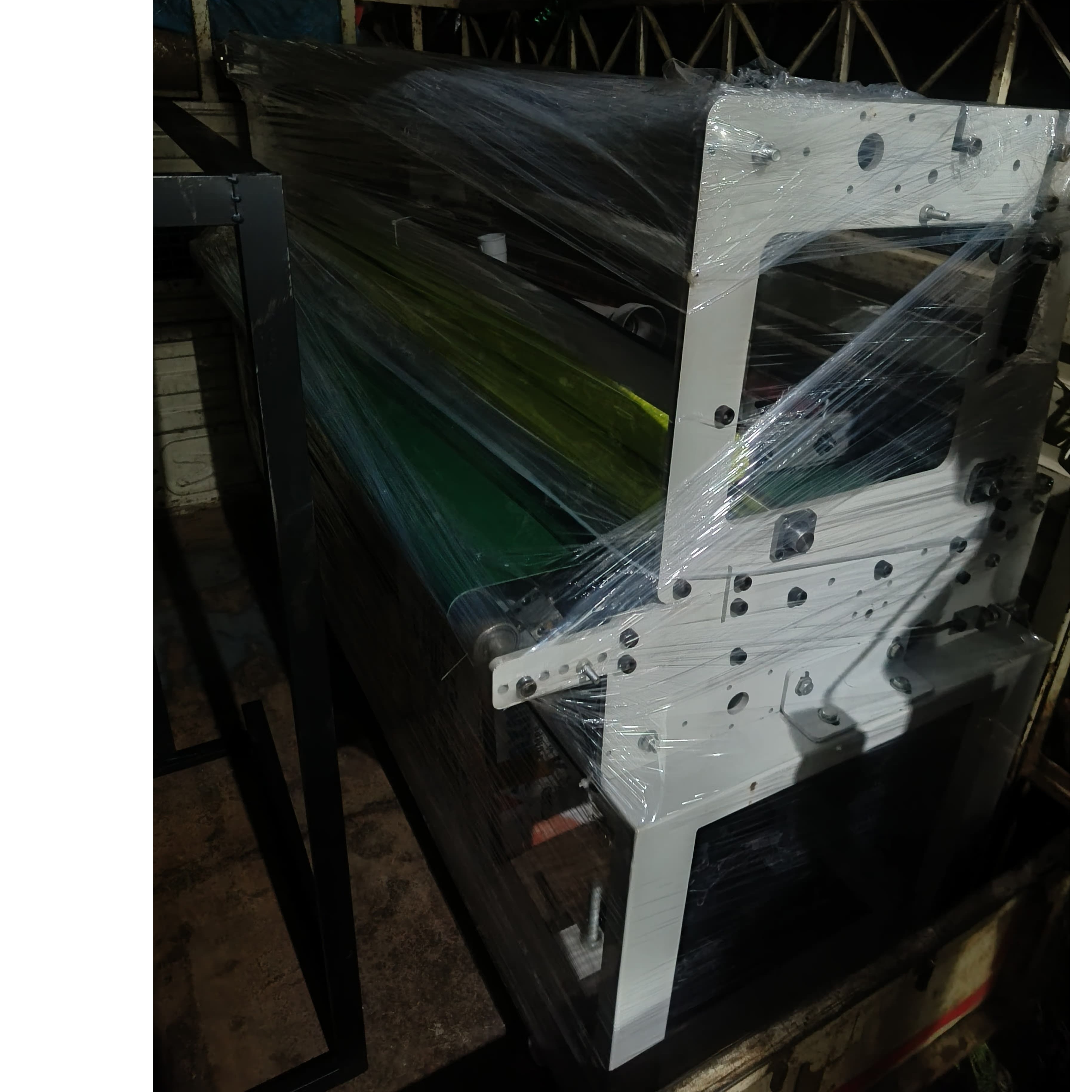

- A roll-to-roll paperless rhinestone transfer machine revolutionizes the way rhinestones are applied to fabrics. By automating the process and eliminating the need for transfer paper, these machines offer significant improvements in efficiency, precision, and cost-effectiveness. They are particularly valuable for high-volume textile production, enabling manufacturers to produce intricate and customized designs on a large scale with minimal waste and labor.

- A paperless rhinestone transfer machine is a specialized

device used in the fashion and garment industry to apply rhinestones, studs,

and other embellishments onto fabric without the use of transfer paper.

These machines use advanced technology to pick and place

rhinestones precisely on a garment or fabric, facilitating the creation of

intricate and custom designs.

Key features typically include:

Automated Process: The machine automates the picking and placing of rhinestones, increasing efficiency and precision compared to manual methods.

Design Software Integration: They often come with or support design software that allows users to create and upload custom patterns and designs.