-Design Creation: Users create or import rhinestone designs

using specialized software. These designs specify the exact placement and size

of each rhinestone.

-Rhinestone Feeding: The machine is equipped with hoppers

or feeders that hold different sizes and colors of rhinestones.

-Placement Mechanism: The machine uses a vacuum or

mechanical picker to pick up rhinestones from the feeder. Advanced sensors and

precision motors ensure accurate placement of each rhinestone according to the

design.

Direct Application:

Instead of using transfer paper, the machine directly

applies rhinestones onto the adhesive surface of the fabric or a transfer film

that will later be heat-pressed onto the fabric. The direct application is

often controlled by a combination of air pressure, heat, and adhesive.

Heat Pressing:

Once the rhinestones are applied to the adhesive surface, a heat press is used to permanently fix the rhinestones to the fabric. The heat activates the adhesive on the rhinestones, bonding them to the fabric.

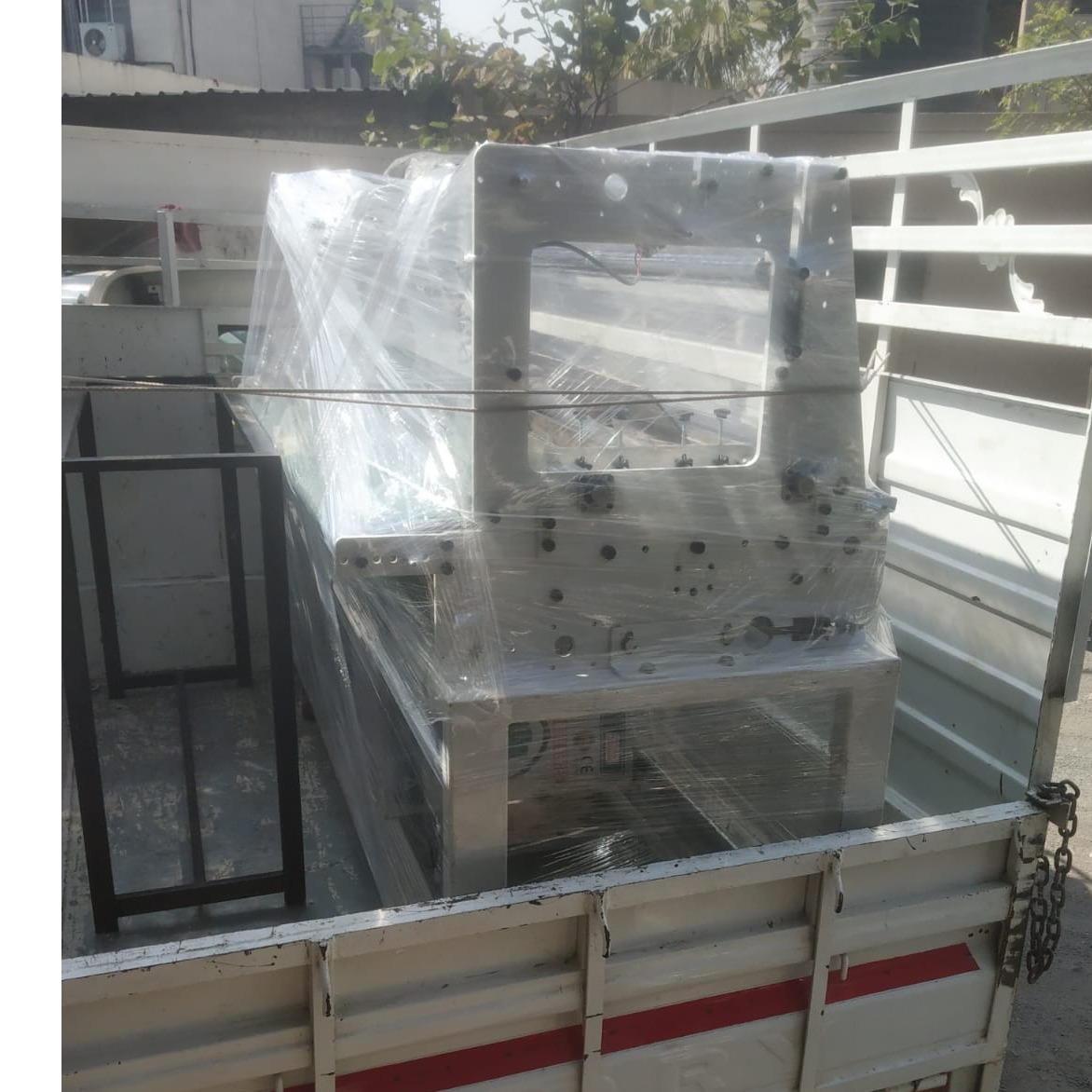

The paperless rhinestone

machine is an innovative technology used in the rhinestone transfer

industry. Unlike traditional methods that require paper backing, this machine

allows for the direct transfer of rhinestone designs onto various fabrics. Here

are some key features and details about paperless rhinestone machines:

Direct Fabric Transfer:

The paperless rhinestone machine

enables direct transfer of rhinestones onto fabric without using any paper or

film.

It eliminates the need for a

separate step involving paper backing, making the process more efficient.